This blog covers enhancements to part repair processes covered in a previous blog. This iteration of the enhancements makes the repair process easier to manage.

1. Create a Part Repair WO

There are two ways to create a part repair work order.

- Menu: Inventory | Transactions | Create Repair WO (Checkout). A part is checked out from stock, and a repair WO is created.

- The repair process includes a part checkout transaction and repair WO creation.

- Menu: Inventory | Transactions | Create Repair WO (Checked out). A part has been checked out previously. A repair WO is created for it.

- The process does not require one to return a part to inventory to have a repair WO created.

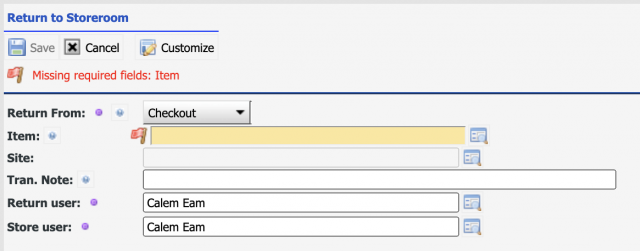

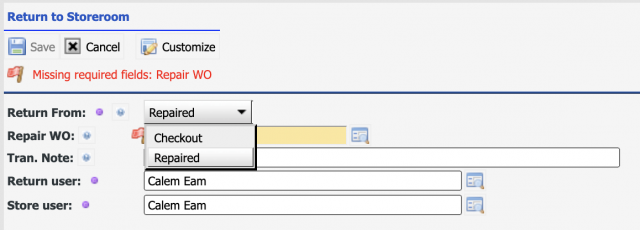

2. Return Parts Repaired

The return process includes both parts checked out, and parts repaired internally. A dropdown is introduced for one to pick what return process to use.

- Menu: Inventory | Transactions | Return to Storeroom

- For parts checked out, select "Checkout" dropdown, and enter a part number to return.

- For parts repaired, select "Repaired" dropdown, enter its repair work order number to return.

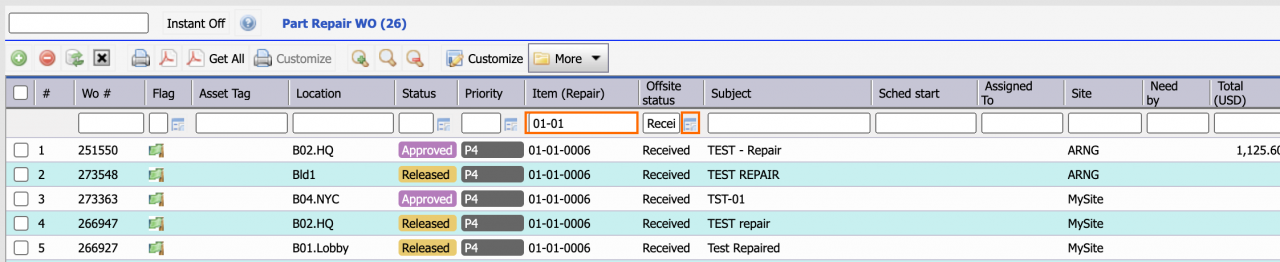

3. Part Repair WO

A new list form is available from release R2022a to show all work orders for part repair.

- Menu: Work Order | Open | Part Repair WO

- One can search the list by item number, Offsite Status, and other fields.

4. Rollback a Part Repair WO

In case a part repair WO is created by mistake, one can revert the process by canceling its repair WO.

- Edit a work order and change its status to "Canceled".

- The part stays checked out. One may return the part as a normal checkout, or create a repair WO from its checkout transaction later on.

- The cancellation may not be allowed as follows:

- The part is on a REQ. The REQ needs to be canceled in order to cancel the repair WO.

- The part is sent to a vendor.

- The part is received to a storeroom.

- The part is retained by a vendor.

5. Part Repair WO with Qty > 1

One may create a repair work order of internal repair for more than one part of the same item number.

- For instance, there are 5 spare parts (of the same item number) to be repaired internally. You may check out 5 parts to create a repair work order; or create a repair work order for 5 parts checked out in a transaction.

- Repair work orders with repair qty over 1 cannot be placed in a repair REQ or PO.

- Offsite repair work orders should be created with only 1 spare part.

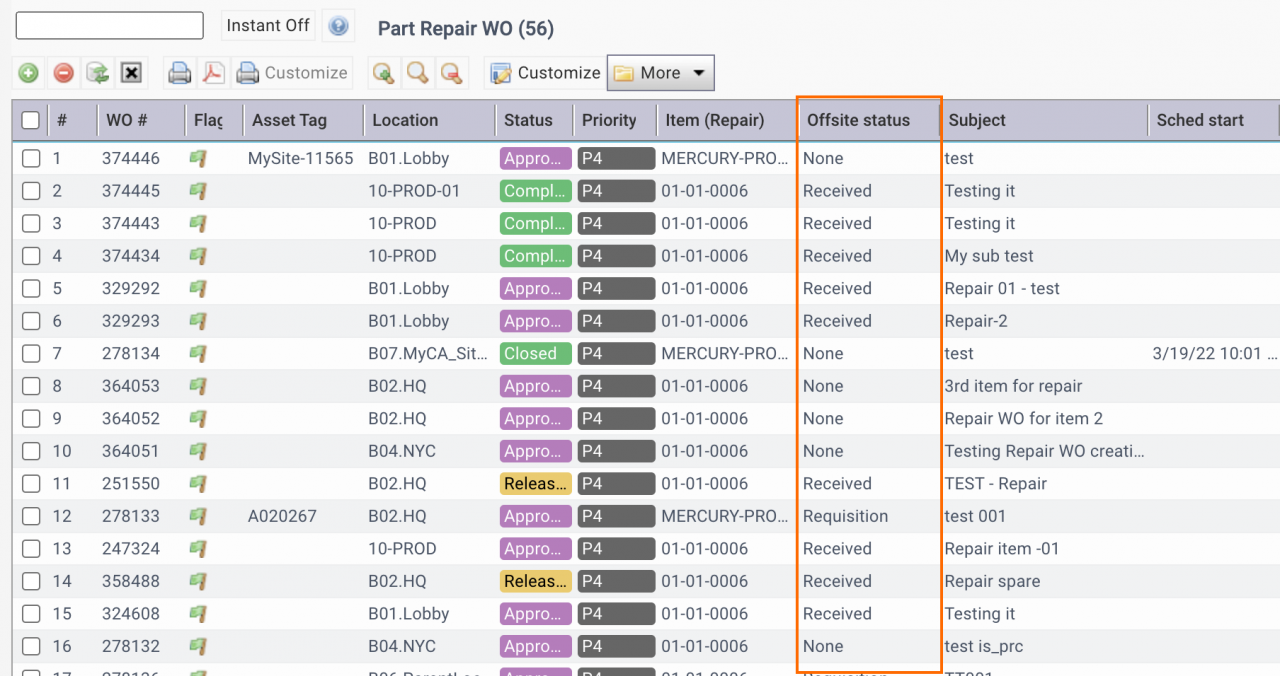

6. Internal and Offsite Repair

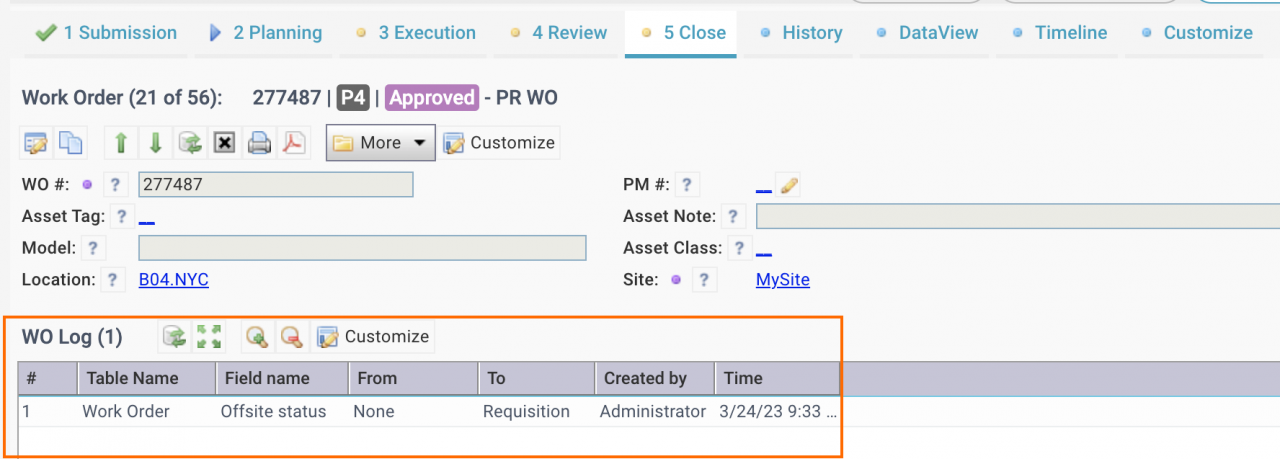

A repair WO can be placed on a repair requisition to be sent for offsite repair. You can tell if a part is repaired internally or offsite by examining its "Offsite status".

- Menu: Work Order | Open | Part Repair WO

- The offsite status indicates the lifecycle of the part repair. One can search for a combination of the dropdown values:

- None - Internal repair

- Requisition - the part is for offsite repair and a REQ has been created for it.

- Sent - the part has been sent to a vendor for repair

- Received - the repair is done (internal or offsite) and returned to storeroom

- Retained - this is for offsite repair, the part is replaced and the original part is retained by vendor.

- The history of "Offline status"changes are recorded in work order logs (screenshot below).