Calem Blogs

How to Prevent Over-Ordering of Spare Parts

In Release R21e a process is introduced to prevent ordering parts excessively. The process can help control the maintenance cost without affecting your maintenance operations.

1. Define Minimum and Maximum Stock Level

The first step is to introduce minimum and maximum stock levels for your critical and expensive parts. Auto-requisition should also be enabled so that Calem will generate a requisition if a part falls below the minimum stock level.

2. Prevent Over-Ordering

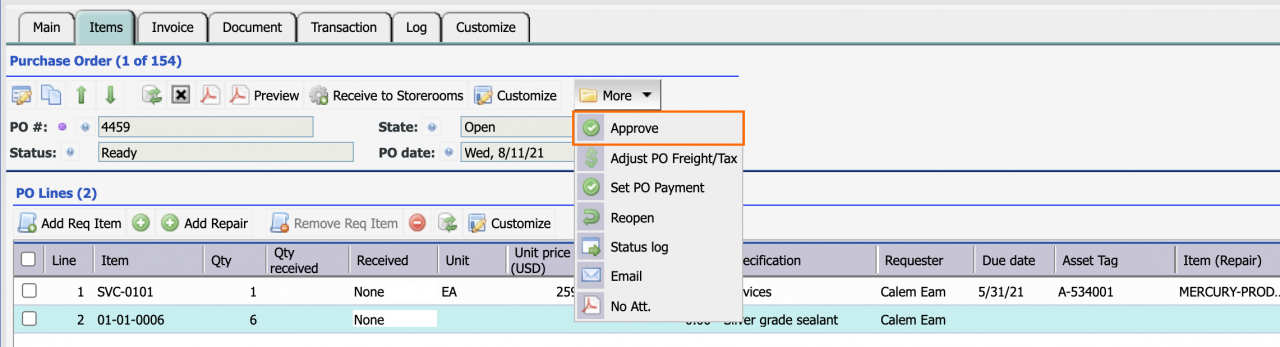

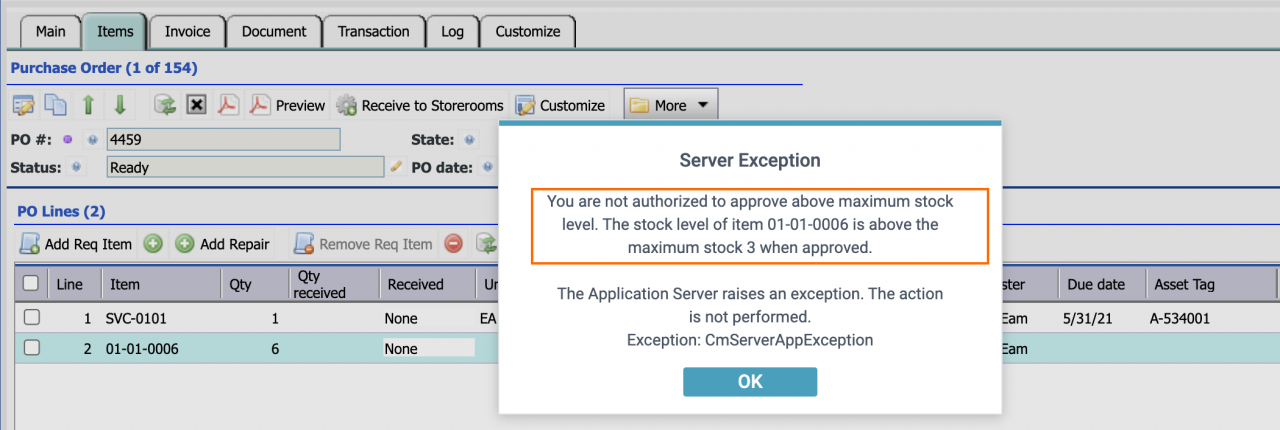

The min/max stock levels are checked when a requisition or a purchase order is approved. If maximum stock level is exceeded, Calem will raise an exception. When ordering 6 items of "01-01-0006" in a PO, an exception is shown when the PO is approved.

3. Authorize Over-Ordering

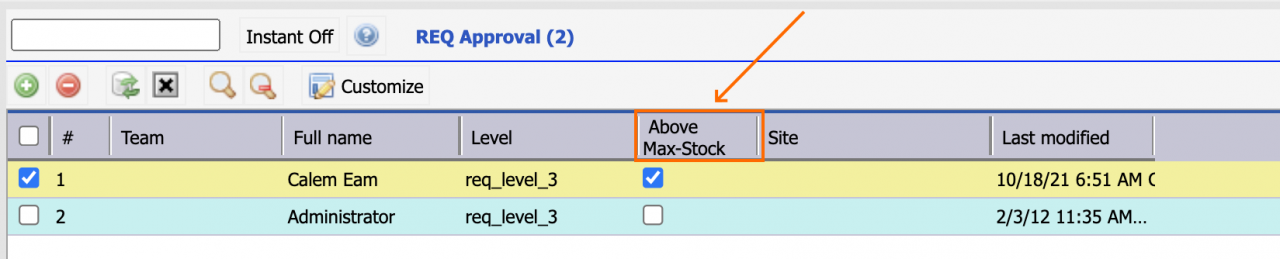

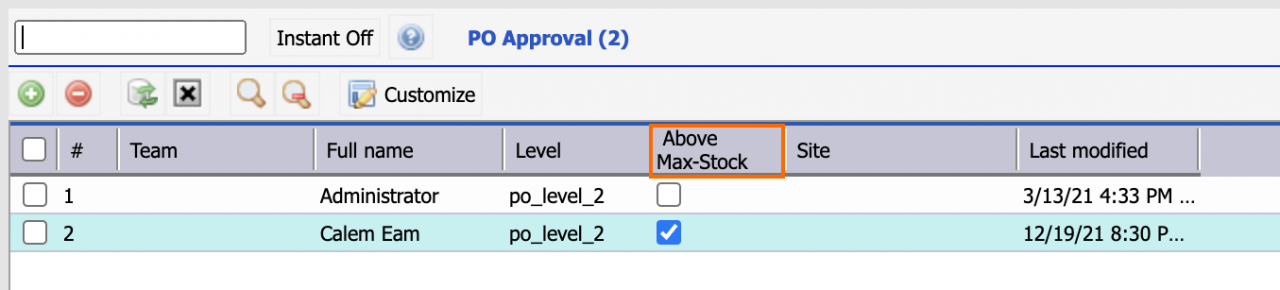

A new flag "Above Max-Stock" is introduced in REQ and PO approval. Enable this flag to authorize approvers to approve REQ/PO that will exceed maximum stock levels.

Additional resources

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://eam.calemeam.com/