Calem Blogs

Calem AI: Estimating Asset Failure by AI (artificial intelligence)

This blog is deprecated - see this blog for asset failure prediction.

AI (artificial intelligence) gives rise to new possibilities in solving problems in enterprise asset management. It is one of the new technologies for Industry 4.0. Preventing unexpected breakdown is one of the key objectives of maintenance. AI may shed light on new approaches to it.

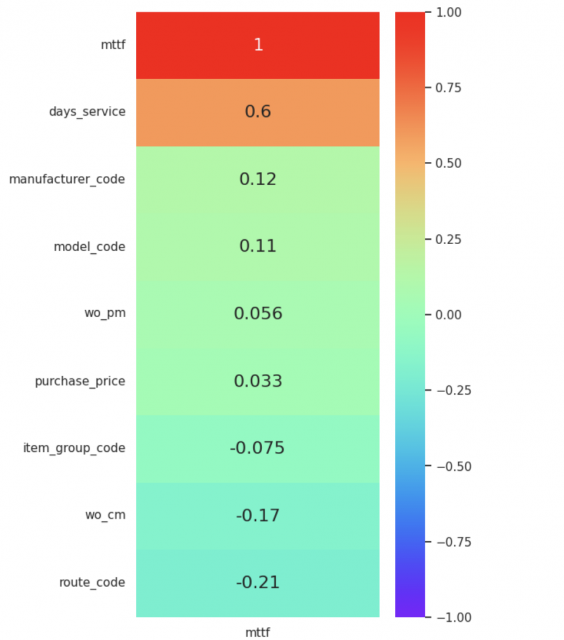

This blog presents a case to estimate asset failure based on machine learning. The case is for assets deployed in roadways. Asset failure history is extracted from work orders in Calem. A statistical mean time to failure (mttf) is derived based on asset failure history. There are asset fields related to an asset failure mean time. For instance, in the correlation heatmap below, time in service (days_service), manufacturer (manufacturer_code) and model (model_code) are the top 3 fields positively related to mttf.

The following fields are used in estimating asset failure time.

| wo_cm | Count of repair work orders |

| wo_pm | Count of preventive work orders |

| days_service | Days a device is in service |

| purchase_price | The price of a device |

| mttf | Statistical mean time to failure |

| item_group_code | The item code of a device |

| route_code | The route code where a device is deployed |

| manufacturer_code | The manufacturer of a device |

| model_code | The device model |

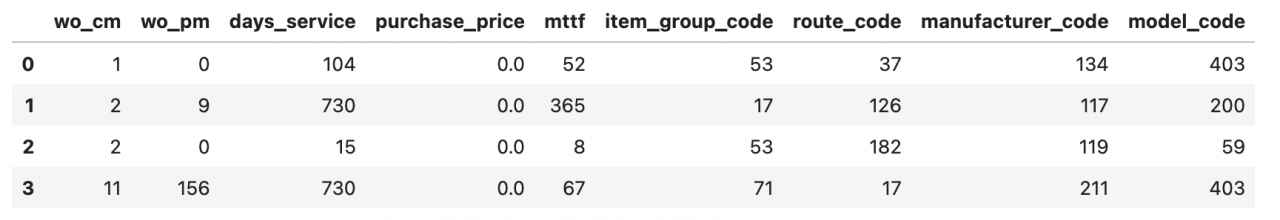

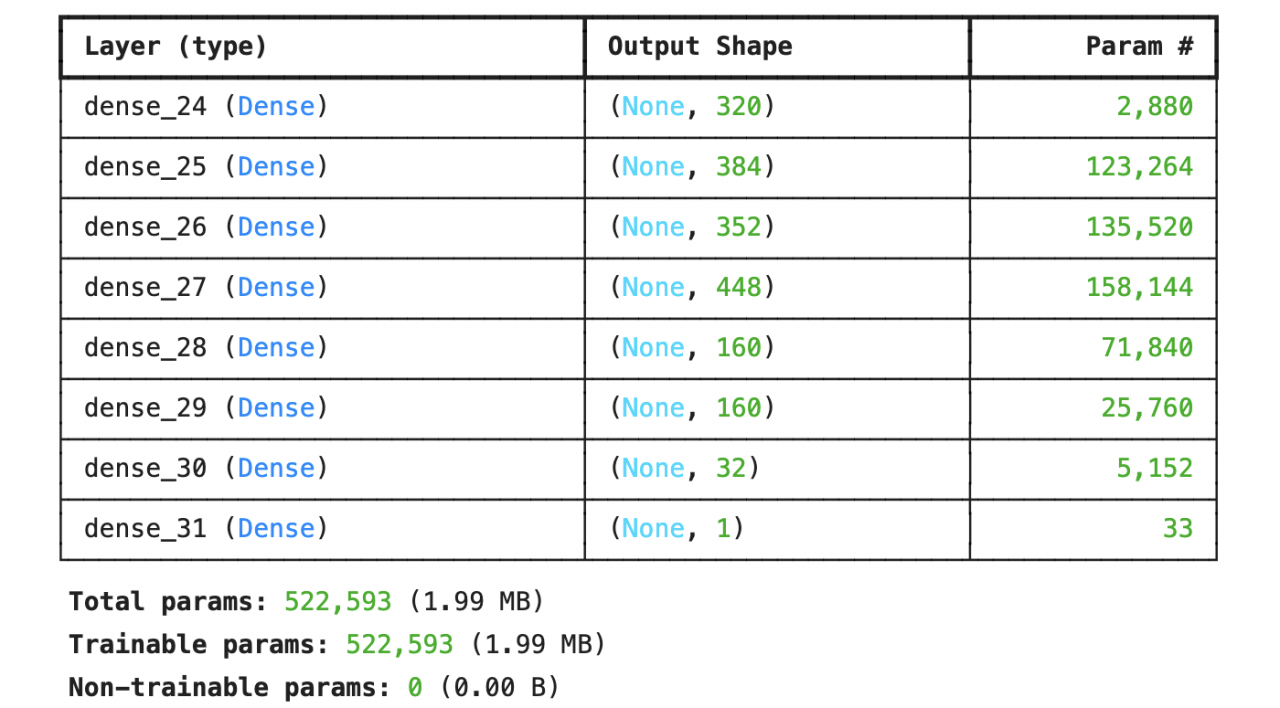

A data set of 5864 rows is prepared for training and validation. The statistical mttf is used to train a model of machine learning to predict the mttf with consideration of fields list above.

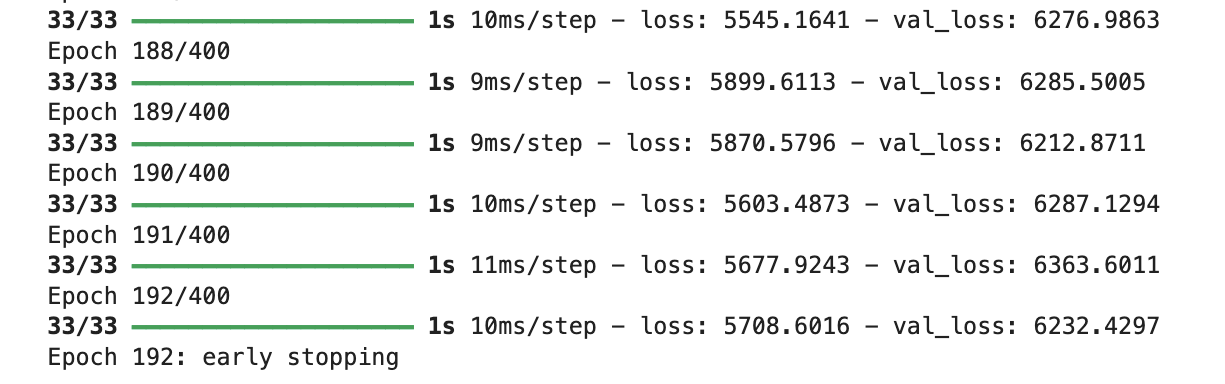

Early stopping is used to avoid overfitting in the training process.

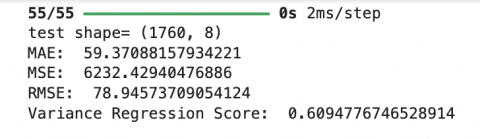

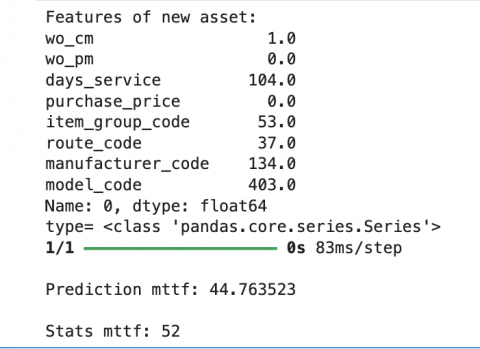

The model has a regression score of 0.61 (best score is 1.0). Average error is 59 days. For example, an asset with a statistic mttf of 52 is predicted to fail in 45 days.

A total of 9 fields are used in this case study. Additional fields may be identified based on client requirements in estimating asset failure time.

Additional Resources

- House Predictions (Keras)

- Calem AI: Asset Failure Prediction by AI (artificial intelligence)

- Calem AI: Why Adopting AI (artificial intelligence)

- Track Failures in Work Orders

- Asset Lifespan Alerts

- Asset Timeline View

- User Guide and Admin Guide (customer account required)

- Calem Enterprise Training Site

- Calem Enterprise Blogs

- Calem Enterprise demo

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://eam.calemeam.com/