Calem Blogs

Auto ABC Process for Inventory

Auto ABC Process is available in the coming release of R2024d. It allows inventory staff to prioritize items for ordering control based on their importance. Here is an introduction of inventory ABC process: https://en.wikipedia.org/wiki/ABC_analysis

The ABC process groups inventory items into three categories: A, B and C.

| A Items | Very Important |

Very Tightly Controlled |

| B Items | Important | Tightly Controlled |

| C Items | Less Important | Less Tightly Controlled |

The grouping is based on total usage value for a given period. For instance, the following is an example of ABC classification based on annual usage values.

| ABC Class | % of Items | % of Usage Value | Note |

| A Items | 20% | 70% | 20% of the top items accounting for 70% of total annual usage value. |

| B Items | 30% | 25% | 30% of the items accounting for 25% of total annual usage value |

| C Items | 50% | 5% | 50% of the items accounting for 5% of total annual usage value. |

1. Auto ABC Process

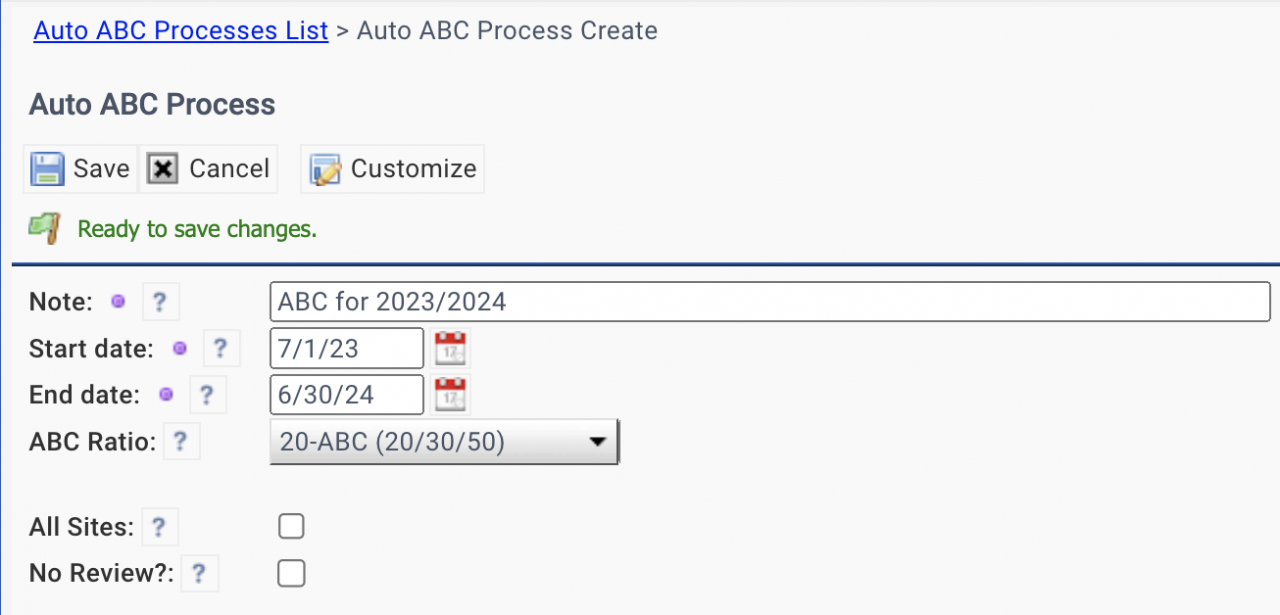

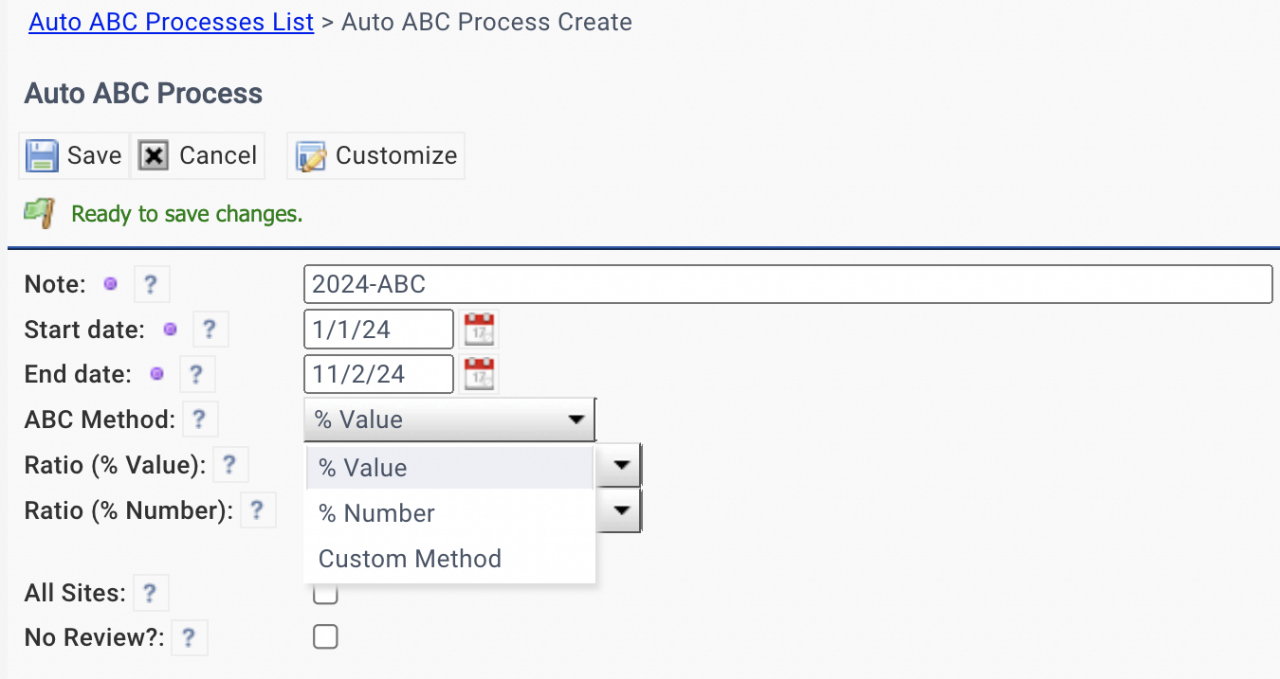

To launch the auto ABC process one needs to create a record for a process.

- Menu path: Admin | Open | Auto ABC Processes

- Create a new record for a process with the following parameters:

- A date range of historical data to calculate new ABC classes. The date range will be determined based on your business requirements.

- Select an ABC ratio. ABC ratios out of the box and custom ratios may be used.

- A custom ratio needs to include the ratios for A and B items. For instance, the A items are the top 15% of items by value. B items are the next top 25% of items by value.

- Calem will calculating the remaining ratio of C items.

- The sum of the ratios of A, B and C is 100%.

- "All Sites" - Check the checkbox to include inventory of all sites. Otherwise, selective sites need to be defined.

- "No Review" - Check the field to do the calculation and application to inventory. Having it unchecked will stop the process after calculation. One may review results and use "Apply" menu to continue.

- Save the record to continue.

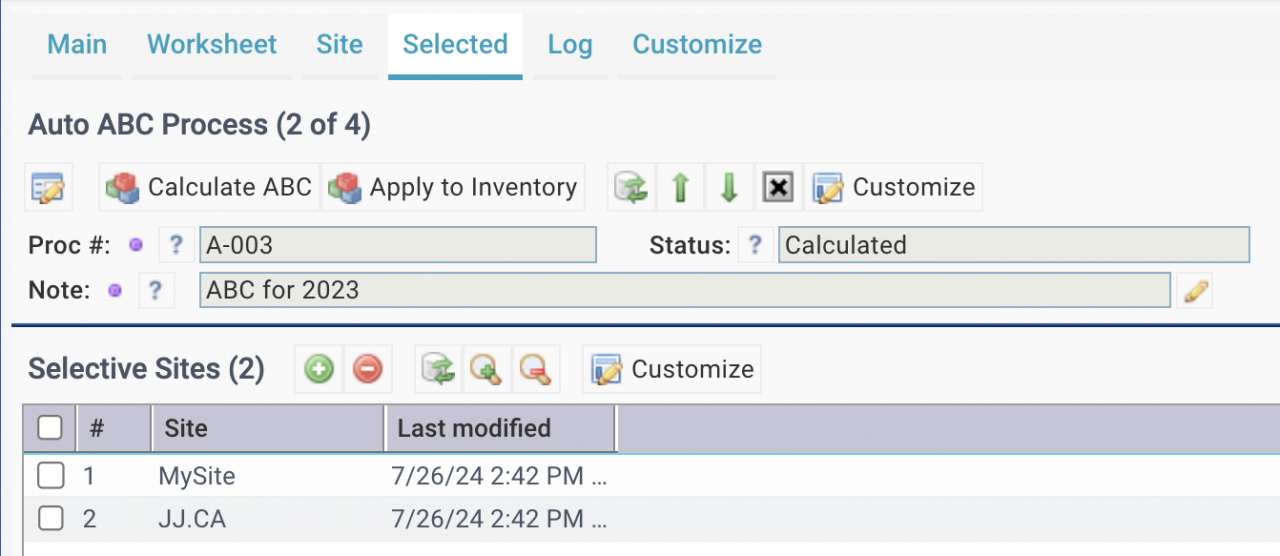

2. Selective Sites

If "All Sites" checkbox is not checked, sites need to be selected to do the process.

- ABC classes are calculated by site.

- The Site form shows the stats of ABC classes calculated in next section.

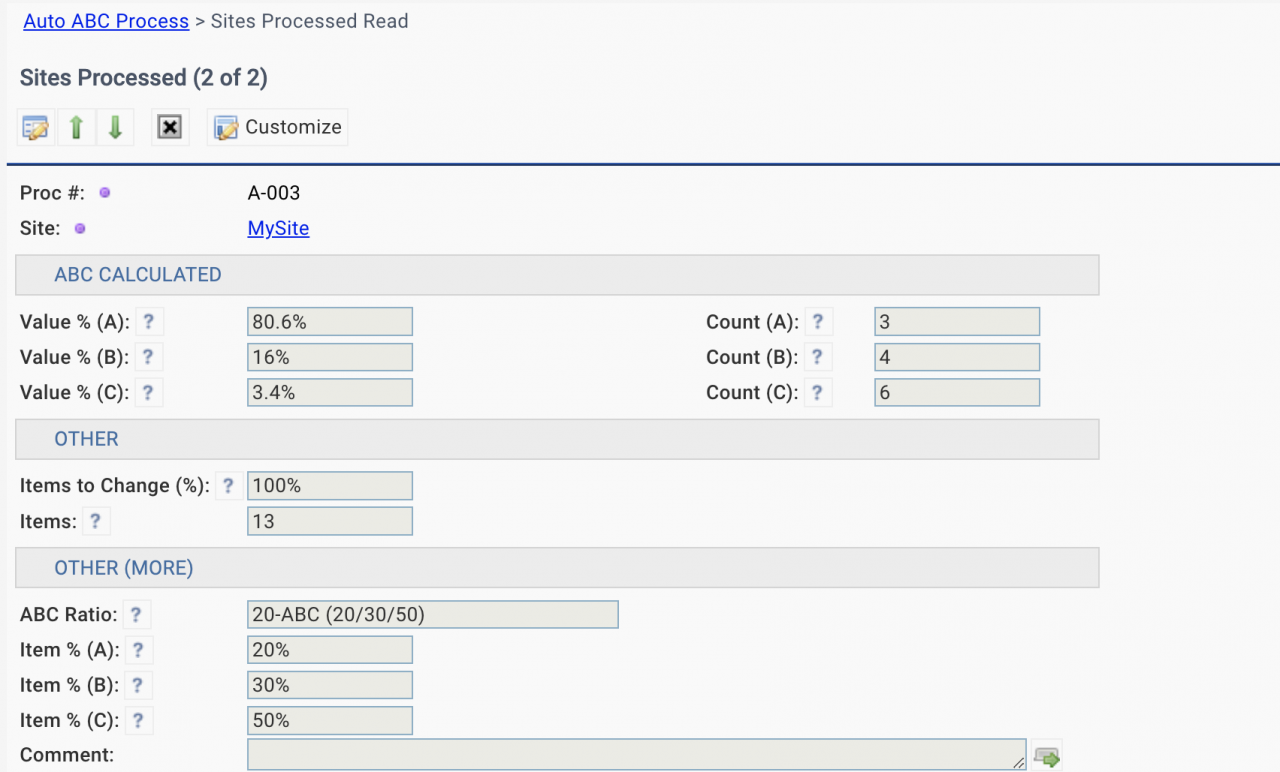

3. Process Execution

The auto ABC process can be executed by menu in the process form.

- "Calculate & Apply" to execute the process from calculating new ABC classes to applying changes to inventory.

- "Calculate" to calculate the new ABC classes, but do not apply to inventories. One may review new ABC values after the calculation.

- "Apply" to apply new ABC values to inventories.

The summary of the process is shown in the screen.

- Value % of items for A, B and C.

- Counts of items for A, B and C.

- Percentage of inventories to change.

- Total count of inventories evaluated.

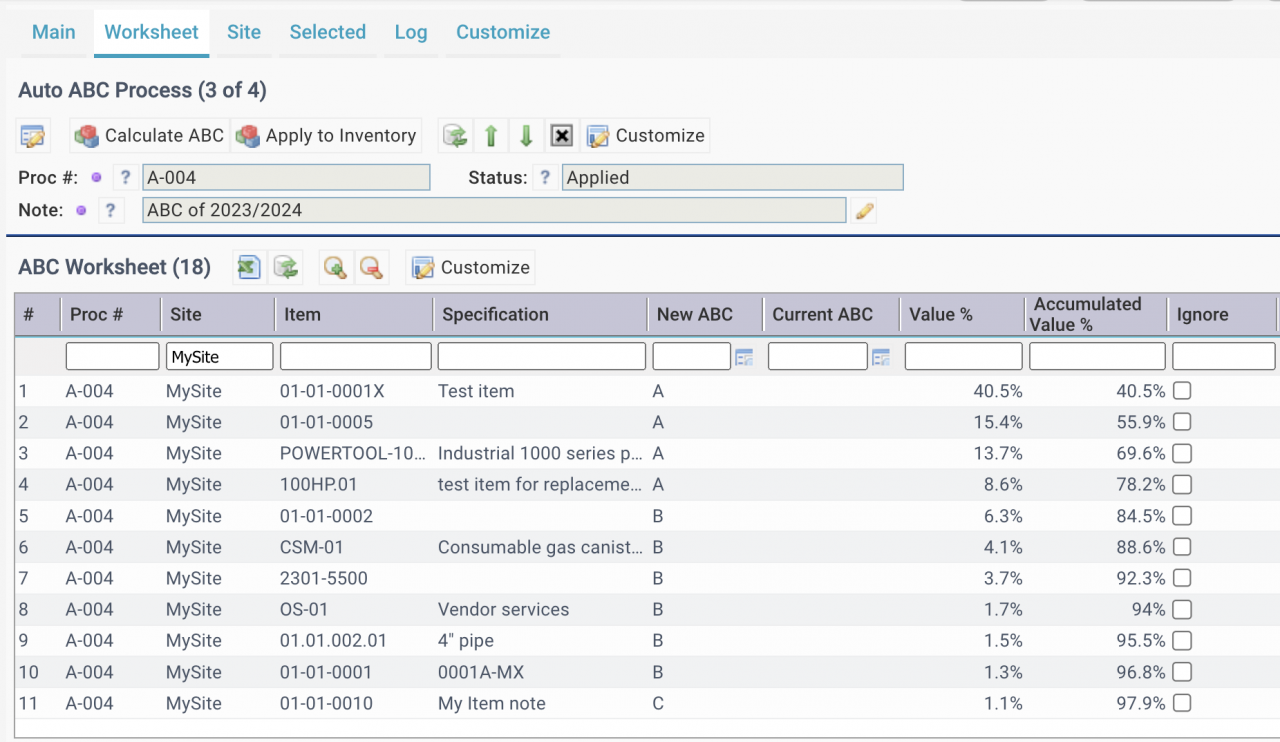

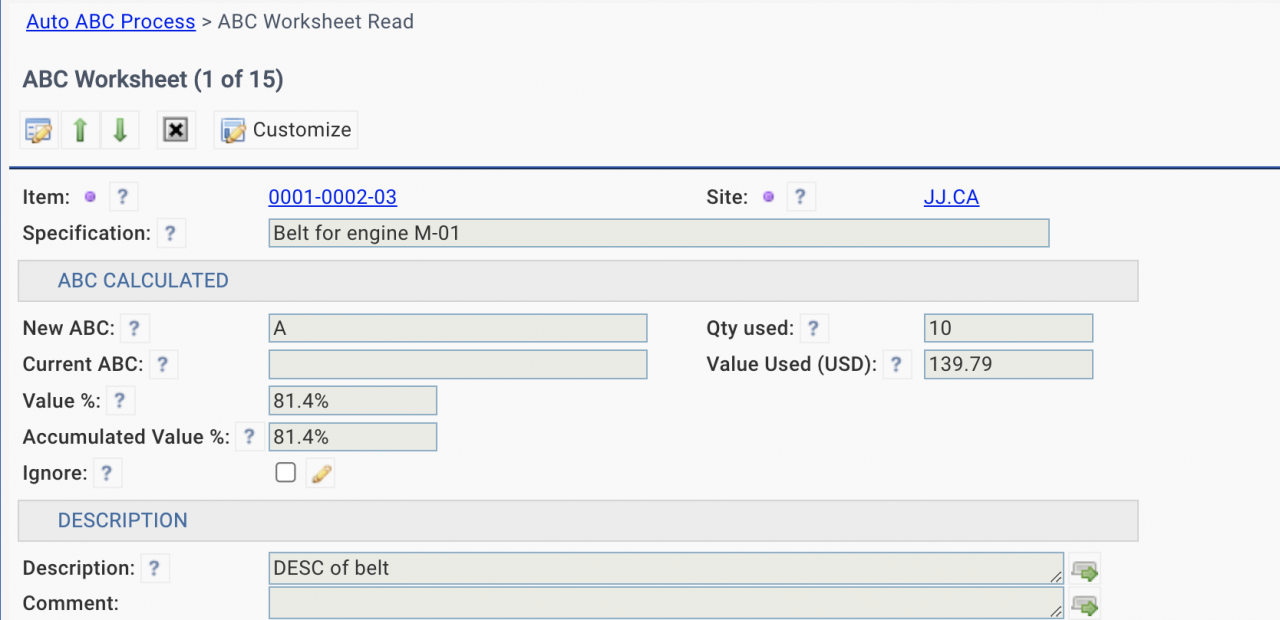

4. ABC Worksheet

The worksheet shows the new ABC classes and factors involved in the calculation.

- Checkout quantities and value are calculated for a given time period. If items are returned within the time period, quantities and values returned are deducted.

- For each site the items are ordered based on values of usage (descending order) for ABC classification.

- New and current ABC classes are shown for each item.

- "Value %" shows the percent of total value of an item over the total value used of all items.

- "Accumulated Value %" shows the percentage of top items (including the item itself) by value over the total value used.

- A flag "No Change?" may be checked so that the calculation is ignored and not applied to inventory.

- The "Worksheet" list may be exported to excel for analysis and update, then, upload back to Calem for application to inventory.

5. ABC Analysis Method

Two methods for ABC classification are supported out of the box:

- By percent of value used. For instance, the top 80% of value used is A, next 15% is B, the remaining is C.

- By number of items. The items are sorted by value used in descending order. The top 20% of items is A, next 30% is B, the remaining is C.

Additional Resources

- ABC Analysis Introduction at Wikipedia

- Auto Min/Max Process for Inventory

- Barcode for Physical Count

- Barcode for Part Checkout

- Clock WO by Asset Scan

- Inventory Checkout by Barcode

- Inventory Module Training

- User Guide and Admin Guide (customer account required)

- Calem Enterprise Training Site

- Calem Enterprise Blogs

- Calem Enterprise demo

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://eam.calemeam.com/