Calem Blogs

How to Manage Inventory Items Individually (or Item Serialization)

Inventory items are managed in bulk by bin/quantities in storerooms typically in Calem. For instance, there are three spark plugs in shelf 1 at the maintenance storeroom. However, managing inventory in bulk might not be sufficient for all organizations. For instance, there are three high precision cameras that need to be tracked in an organization. A camera may be sitting in a storeroom bin, deployed in the field, or in a vendor for repair.

The inventory module in Calem provides serialized inventory to track items individually. This blog discusses steps to manage serialized inventory.

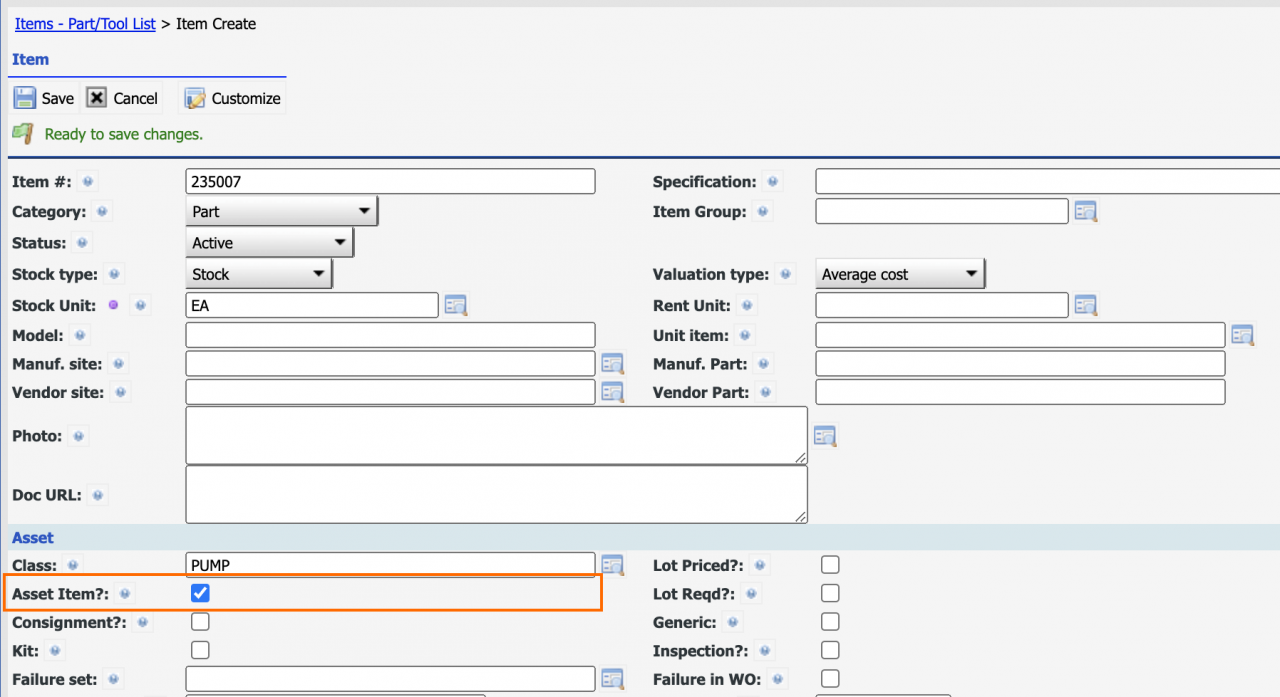

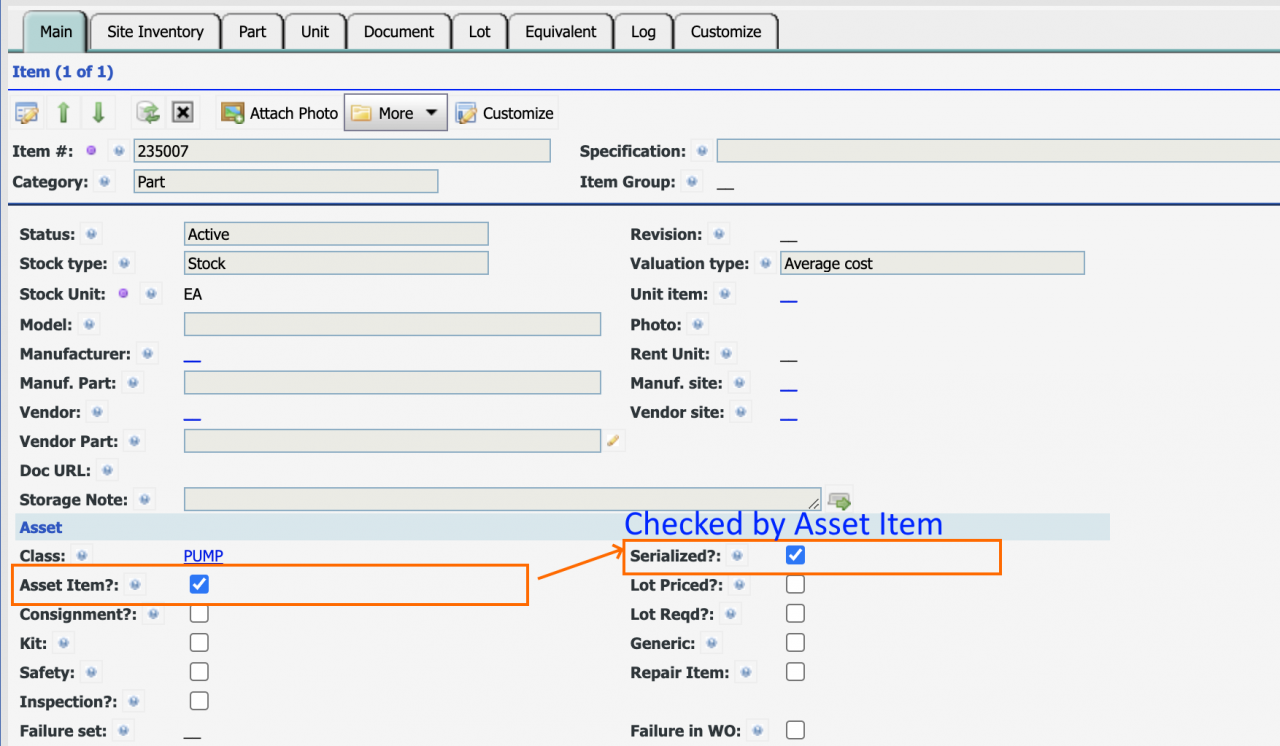

1. Asset Item

The first step is to create an item with "Asset Item" checked.

- Menu: Inventory | Items - Part/Tool | Create

- Set "Asset Item" checked. This flag controls the "Serialized" flag in inventory.

- Serialized inventory are identified by their serial numbers in inventory.

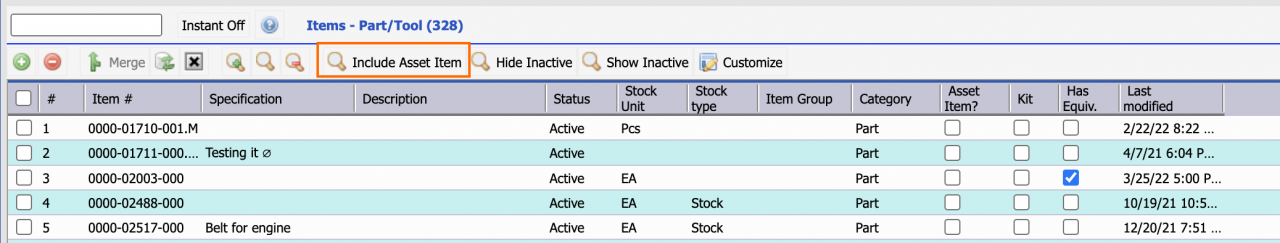

2. Asset Items in "Items - Part/Tool" List

Asset items are not displayed in the "Items - Part/Tool" list when the list is displayed. Click "Include Asset Item" to show asset items.

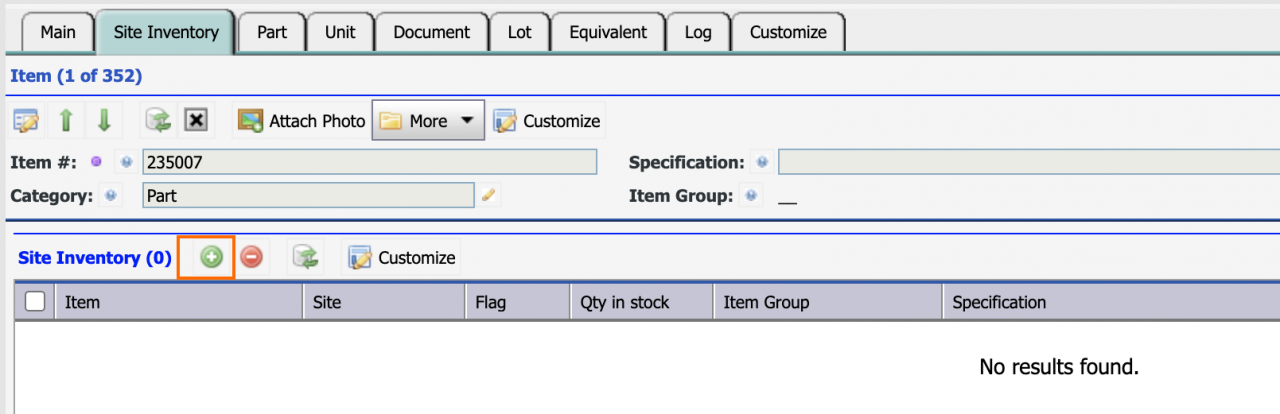

3. Site Inventory

The next step is to create a site inventory for the asset item created above.

- Menu: Inventory | Site Inventories | Create

- Alternatively, menu: Inventory | Items - Part/Tool, open an item, go to the "Site Inventory" tab to create a site inventory.

4. Conversion between Serialized and Bulk Items

There are procedures in Calem to help you adapt to your dynamic business needs. However, the procedures should be used with caution.

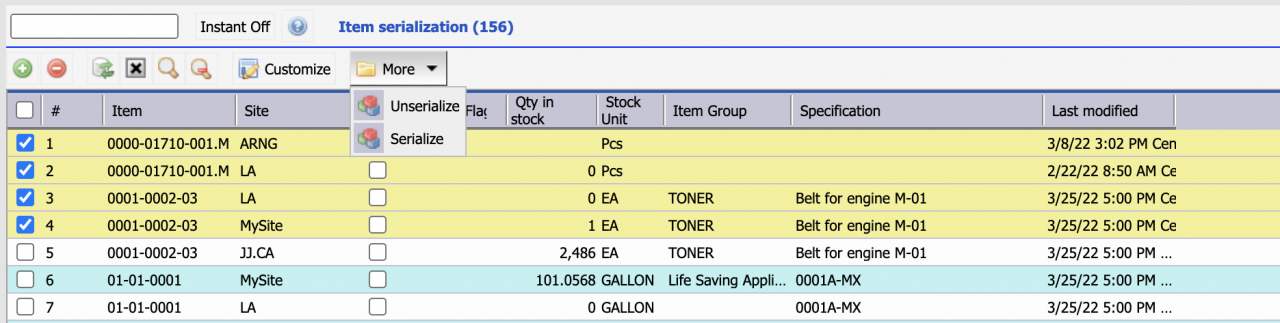

- Menu: Inventory Module | Open | Item Serialization.

- Multiple items can be selected for a procedure run

- We recommend that you plan your inventory serialization up front.

- The procedures discussed here are the last resort if you have not done serialization up front, or your business needs change.

- The procedures serialize or un-serialize current stock in case you have to switch from bulk to serialized, or vice versa.

- The procedures do not apply to transactions completed.

- Inventory transactions might be blocked due to the procedure run.

- For instance, a checkout transaction is done before serialization procedure. The item may not be returned to storeroom after the serialization procedure.

4.1 Process for Serialized/Unserialized

The best time to serialize inventory is up front. If a change has to be made afterwards between serializing and unserializing and item, the following process is recommended.

- To serialize an item:

- Run a report to export the current stock for an item. The report is Inventory | Report | Site Inventory by Bin. Filter the report for the item to serialize and export.

- Do physical count to set stock quantity to 0.

- Edit the item to set "Asset Item" checked.

- Receive items to the bin (based on the export) and enter or have Calem generate serial numbers and asset tags to match the quantity in stock.

- Alternatively, one could use the process above (Serialize menu) to serialize an item. However, asset tags are not created.

- Asset tags may be created at checkout transactions.

- The process above is preferred.

- To unserialize an item:

- Use the process above (Unserialize menu) to unserialize an item.

5. Inventory Transactions of Serialized Inventory

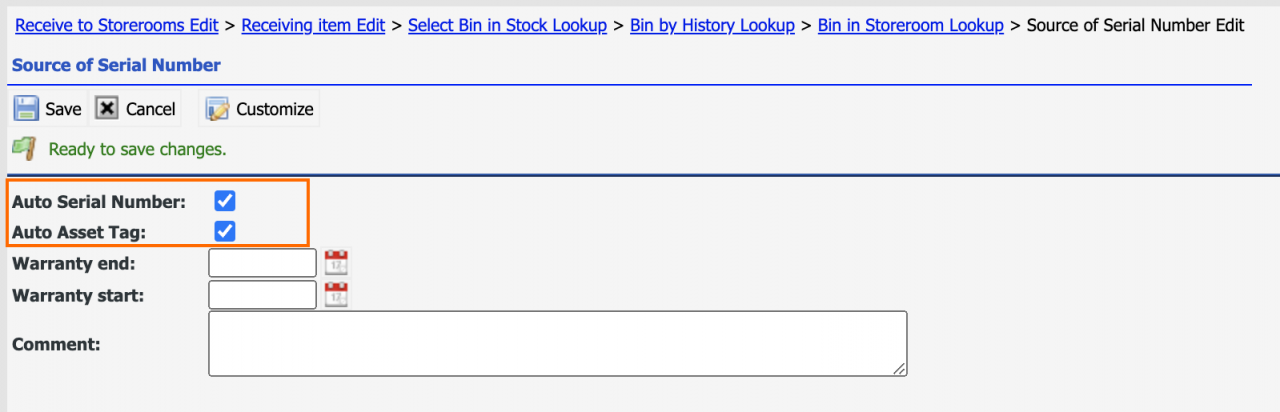

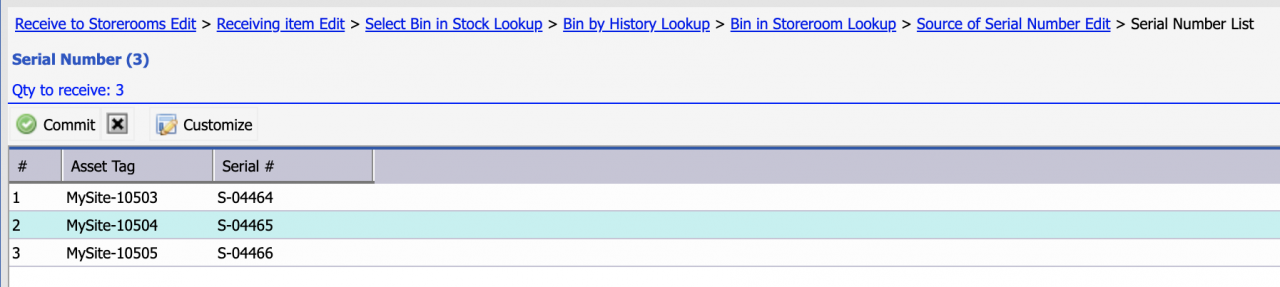

Additional screens and data attributes may be required for transactions of serialized inventory. They are handled properly for you in Calem. For instance, when receiving a serialized inventory, one has to provide serial numbers and assets tags for the items to receive. You may choose for Calem to generate for you, or manually enter them.

Transactions such as checkout and physical count are performed for individual items so make sure the serial numbers match the items transacted.

6. Asset Item Pros and Cons

Asset items are available for managing assets in inventory. An organization may evaluate the pros and cons and decide if asset items should be implemented. One factor is the existence of serial numbers for each asset for management in inventory. Unique serial number may be generated in Calem. They need to be labelled on those assets.

- Pros:

- Asset item allows organization to manage assets in inventory when desired.

- It works perfectly for organizations that are managing assets inventory predominantly.

- Cons:

- Receiving assets requires the provisioning of asset tag and serial number.

- The process to receive all PO items are not allowed - see this blog.

- Physical count requires the specification of serial number.

- Serial numbers should be recorded for each asset part in inventory for identification.

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://eam.calemeam.com/