Calem Blogs

What Part Repair Processes to Choose in Calem

Part repair processes allow organizations to manage inventory stock and track repair cost. Calem provides the following repair processes.

| Repair Process | Note |

| 1. Asset Off-Site Repair |

Repairable parts are managed as assets.

Repair processes are managed from warehouse All repairs are done by off-site vendors. |

| 2. Non-Asset Internal and Off-Site Repair |

Reparable parts are not managed as assets.

Work orders are created for a repair Internal and off-site repair are tracked in the work order Repaired parts are returned to inventory with adjusted prices. |

| 3. Asset Internal and Off-Site Repair |

Reparable parts managed as assets.

Work orders are created for a repair Internal and off-site repair are tracked in the work order Repaired parts are returned to inventory with adjusted prices. |

You may choose a repair process based on business requirements.

| Option | Requirements |

| #1 |

Repairable items are managed individually by own barcodes. Repairs and replacement are done by off-site vendors. |

| #2 |

Repairable items are not individually tracked.

They are managed by quantities in stock. There are no plans to barcode each repair item individually. |

| #3 |

Repair items are managed as individual assets.

Internal and external repairs are supported. |

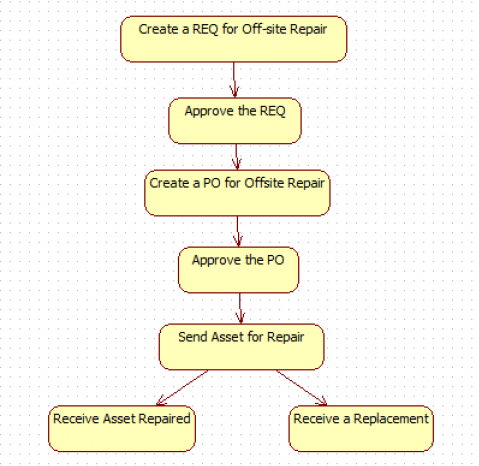

1. Asset Off-Site Repair

Here is the process flow. See this blog for more info.

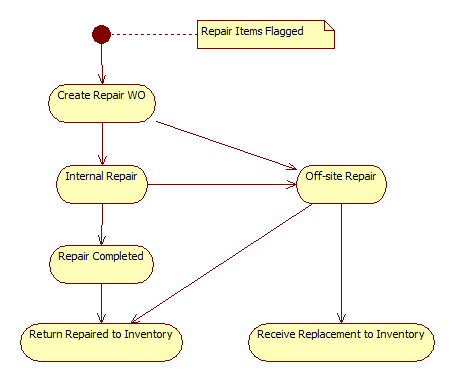

2. Non-Asset Internal and Off-Site Repair

The process flow is shown below. A work order is created to start the repair of a part.

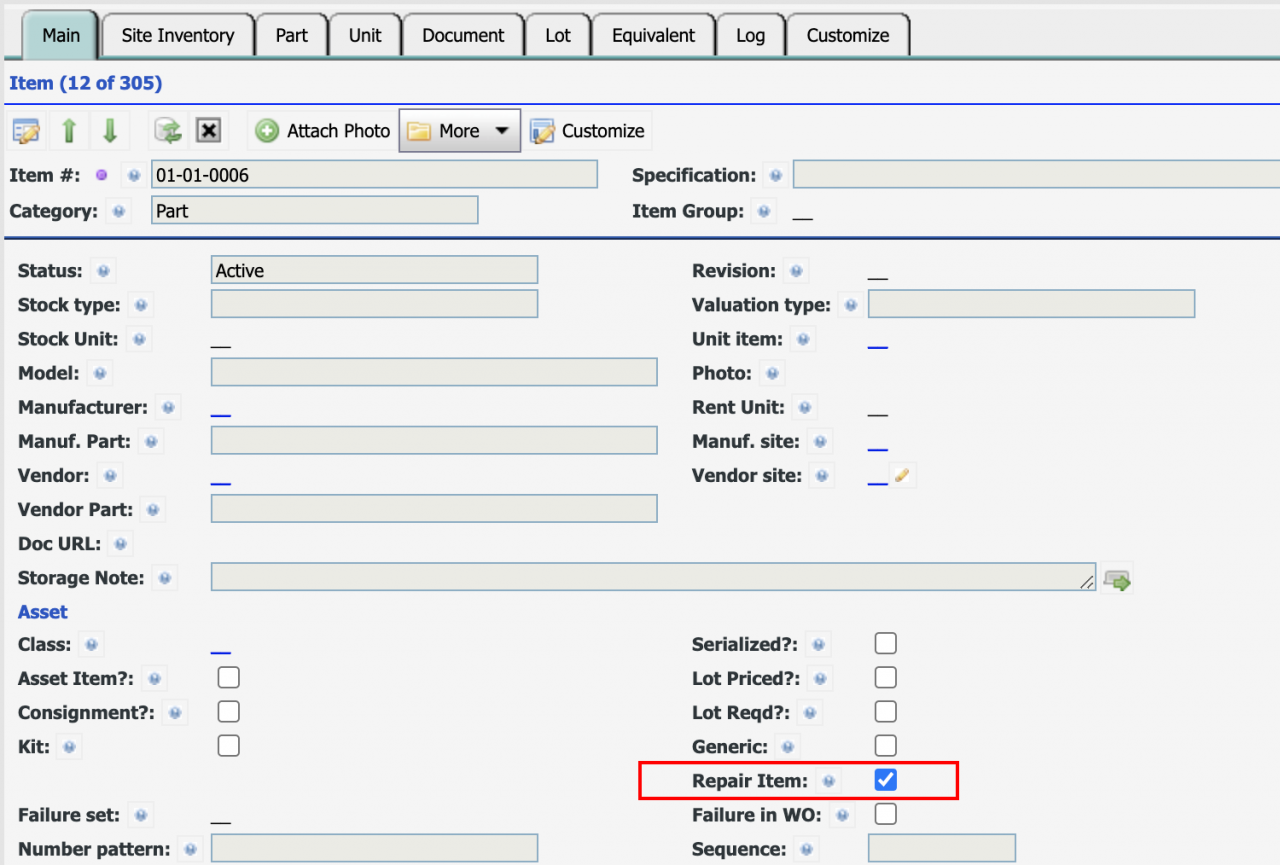

2.1 Flag of Repair Item

The first step is to identify items that will be repaired.

- Menu path: Inventory | Items - Part/Tool. Check "Repair Item" to indicate that an item is repairable.

- Each site inventory can have own flag of "Repair Item" in case that an item is repairable in one site, but not in another site.

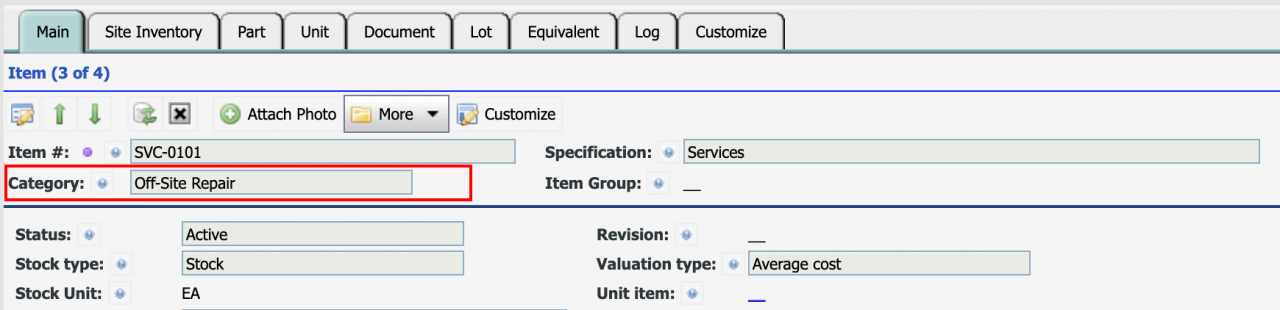

2.2 Item for Off-Site Repair

Next, set up an item for off-site repair.

- Menu path: Inventory | Items - All

- Create an item with category "Off-Site Repair". This item will be used in a requisition and PO to send an item for off-site repair.

2.3 Create a Work Order for Item Repair

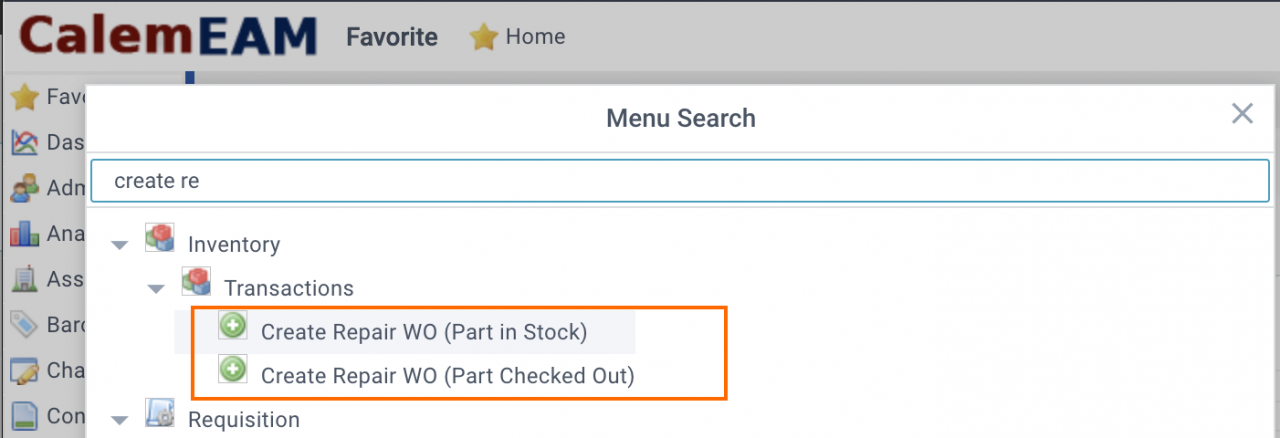

There are two processes to repair a part.

- Option 1. Check out a part to create a repair work order.

- Menu path: Inventory | Transactions | Create Repair WO (Part in Stock)

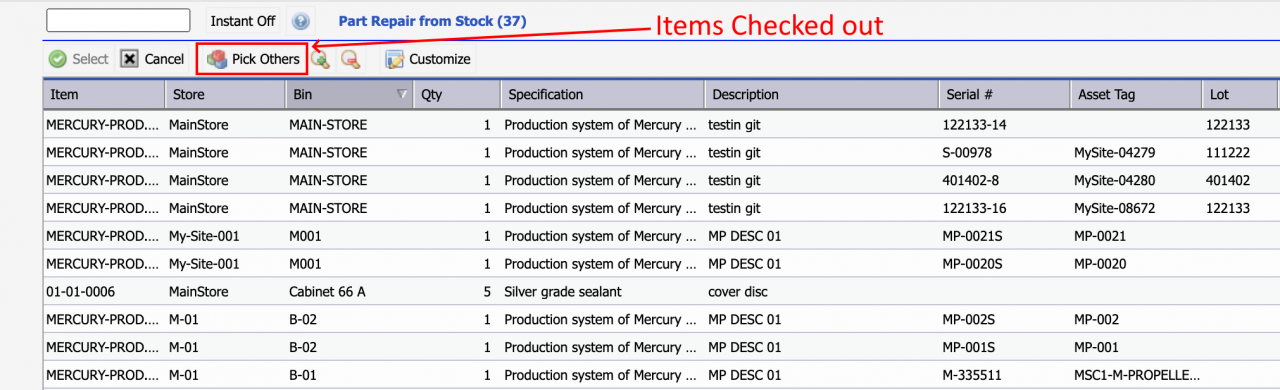

- Select a stock item to repair. The stock item will be checked out from inventory.

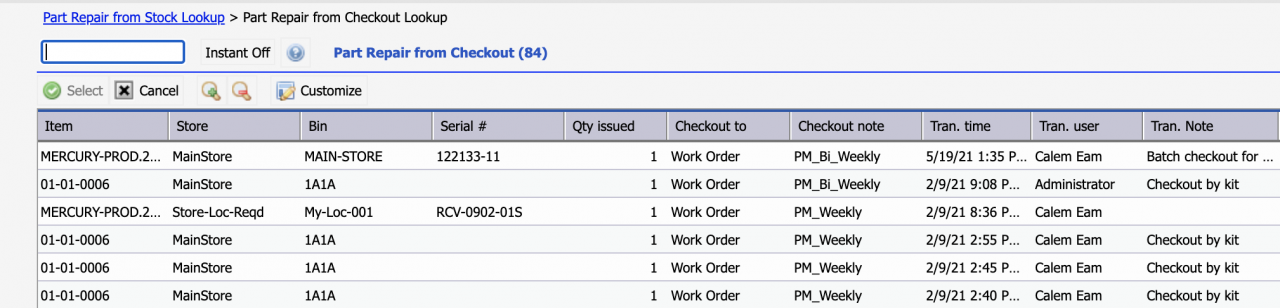

- Option 2: Create a repair work order for a part checked out previously.

- Menu path: Inventory | Transactions | Create Repair WO (Part Checked Oout)

- A part was checked out previously. It was replaced and a repair work order is created for it without returning to inventory.

For option 1:

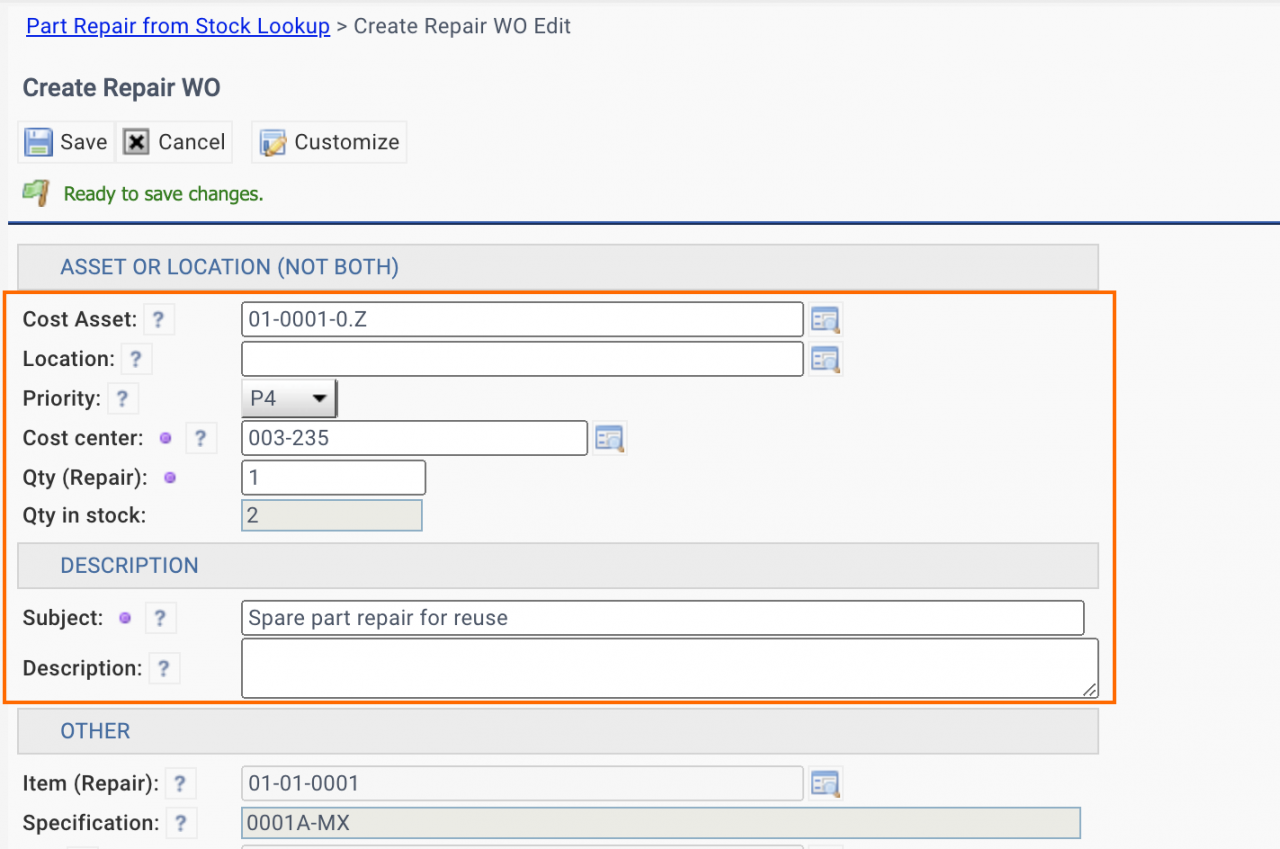

- The work order creation screen is shown.

- Populate cost asset (the asset to charge repair cost to), location, priority, subject and description.

- Click "Save" to create a repair work order.

- Repair work orders have category of "Item Repair".

2.4 Internal Repair and Return to Storeroom

For items that are repaired internally, perform the repair process and return the repaired part to inventory.

- Perform the repair process: a) Check out parts to the repair work orders if parts are needed for the repair; b) Record time spent in the repair work order.

- Complete the work order.

- Return the part to storeroom. Menu path: Inventory | Transactions | Return to Storeroom

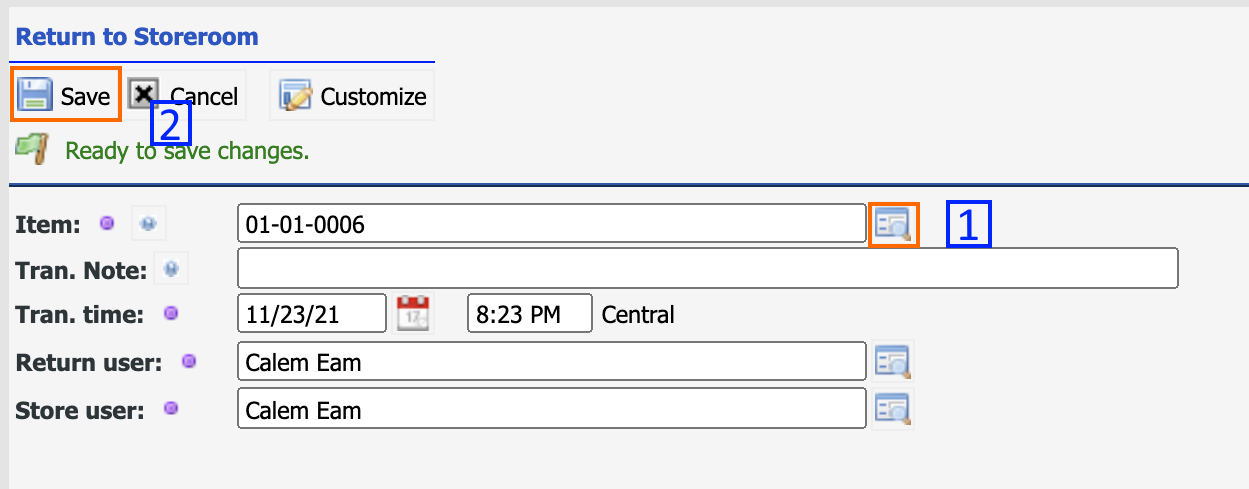

- Use the lookup button to find the inventory to return (1), click "Save" to continue (2).

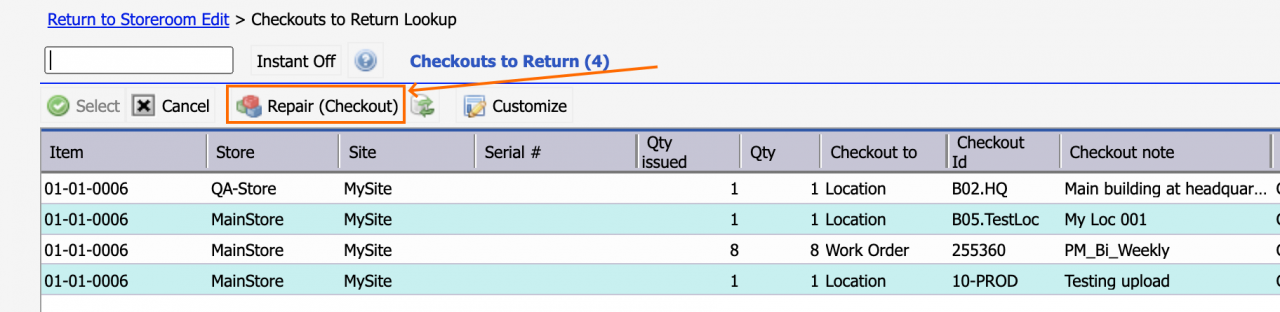

- Checkout transactions are listed for the item. Click "Repair (Checkout)" to return items checked out for repair.

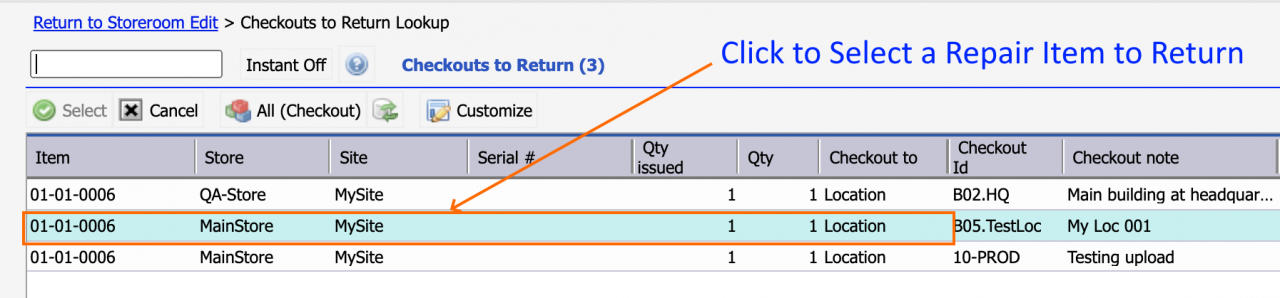

- The items checked out for repair are shown. Click a row to select a checkout transaction to return.

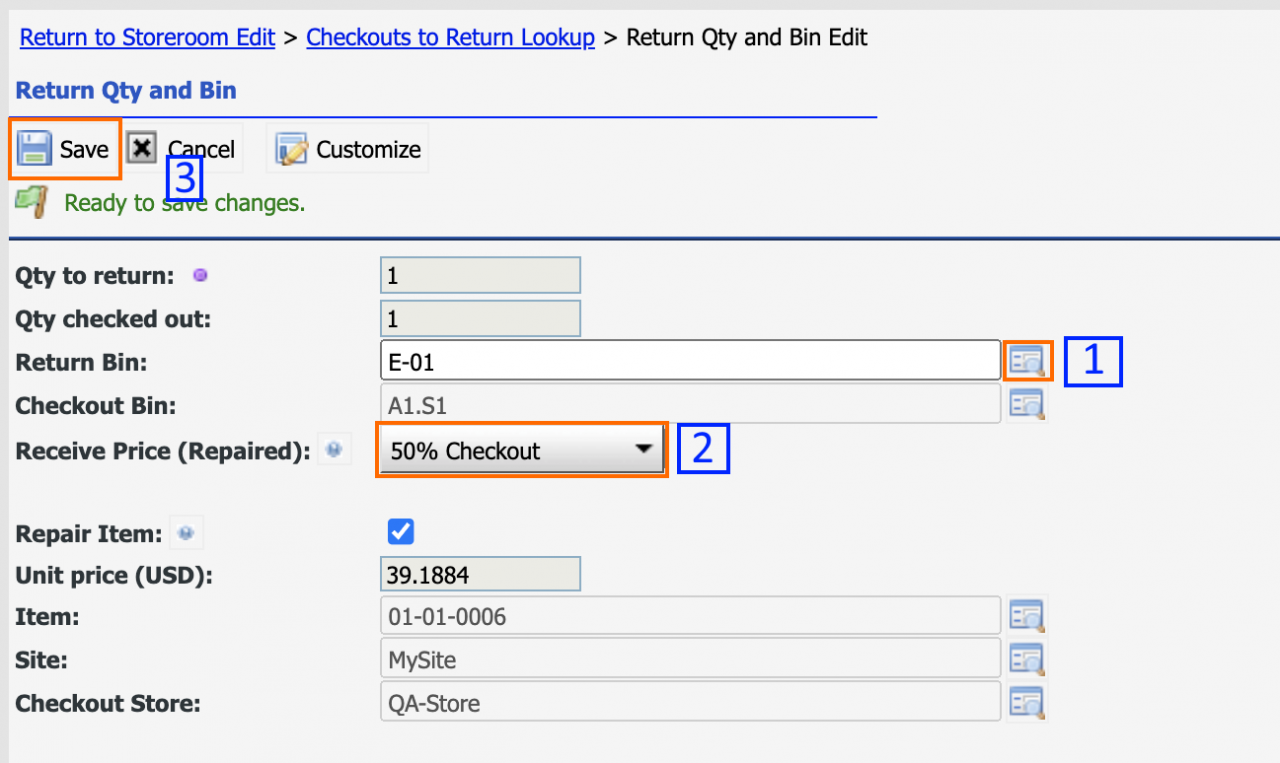

- When returning a repaired item,

- You may return it to a new bin to return the repaired part to storeroom different from the storeroom where the part was checked out (1).

- You may set new unit price for the repaired part to be 50% of the checkout price, the same as the checkout price, or a custom unit price.

2.5 Create a Requisition for Off-Site Repair

For items that need to be sent for off-site repair, a requisition is created.

- Menu path: Requisition | Create Repair

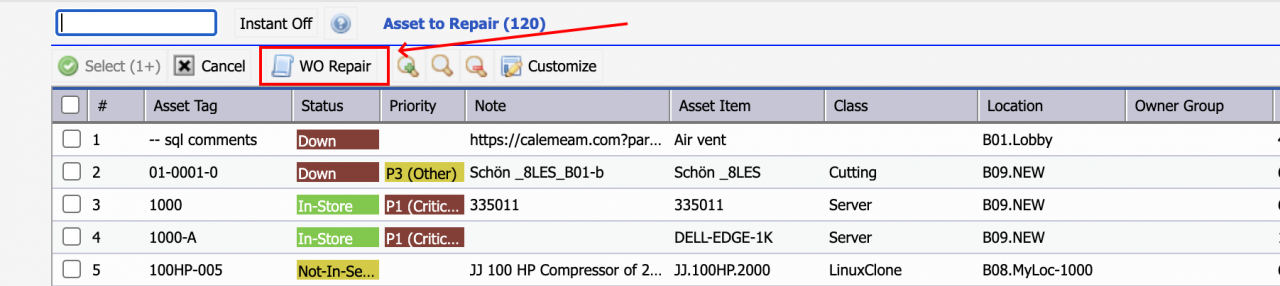

- The asset lookup screen is shown to select an asset for off-site repair.

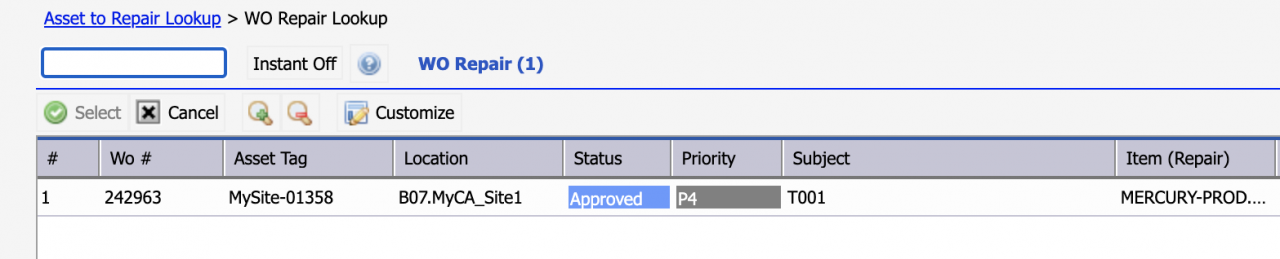

- Click "WO Repair" to pick an item in a repair work order for off-site repair

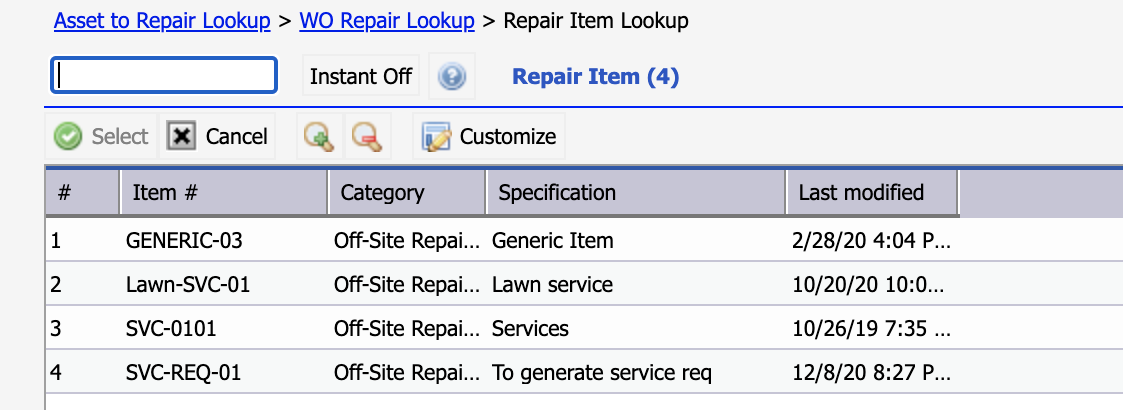

- Next, pick an off-site repair item to be used in the requisition

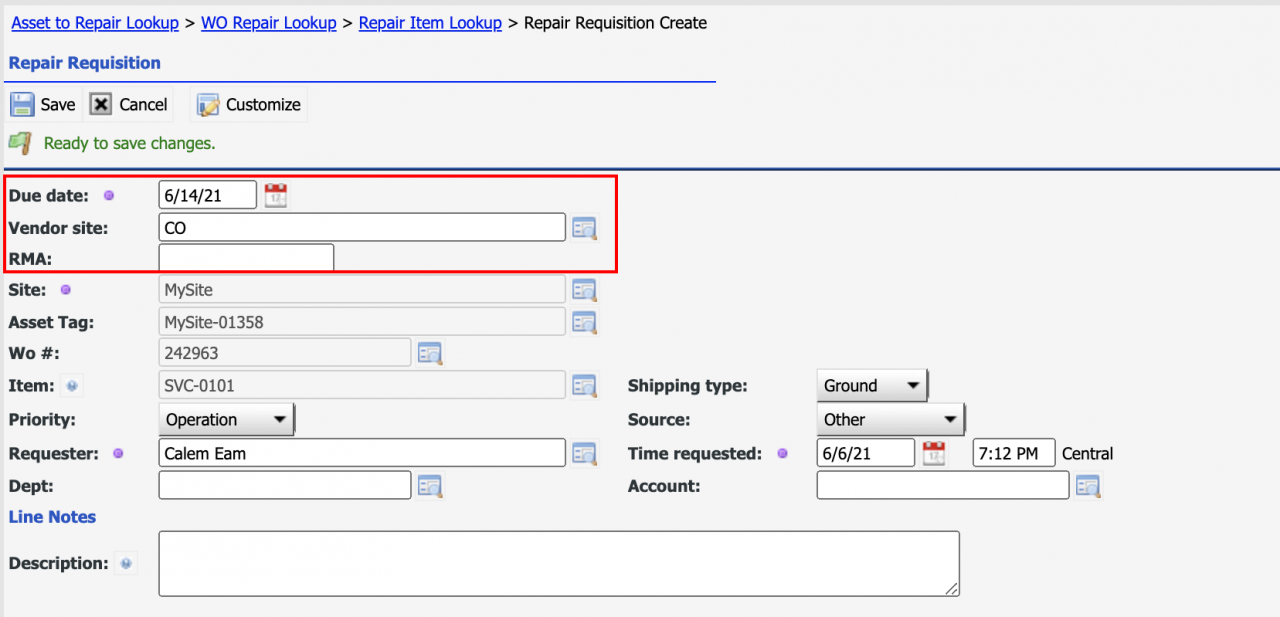

- Finally, populate the due date, vendor site, and RMA (if applicable).

- Click "Save" to create a repair requisition.

2.6 Create a PO for Off-Site Repair

A repair requisition created above will be reviewed, approved and turned into a purchase order. The purchase order will be reviewed and approved.

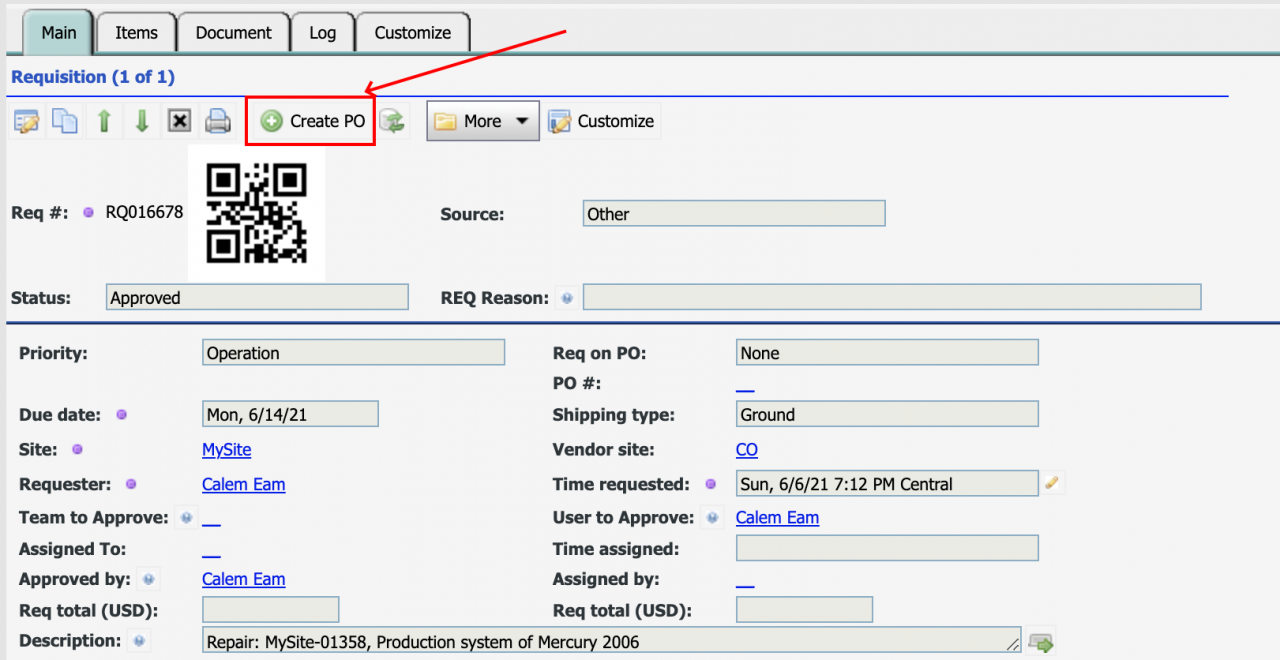

- Menu path: Requisition | Open REQ | Go to a REQ and "Create PO" once it is approved.

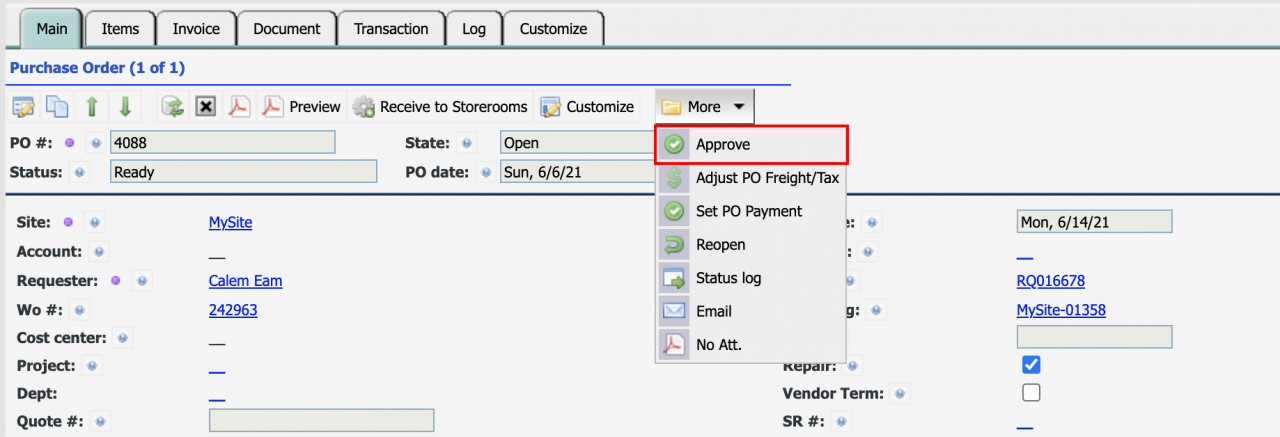

- Menu path: Purchase | Open PO | Go to a PO to approve it.

2.7 Sent Part for Off-Site Repair

An approved PO and the repair part are sent to vendors for repair.

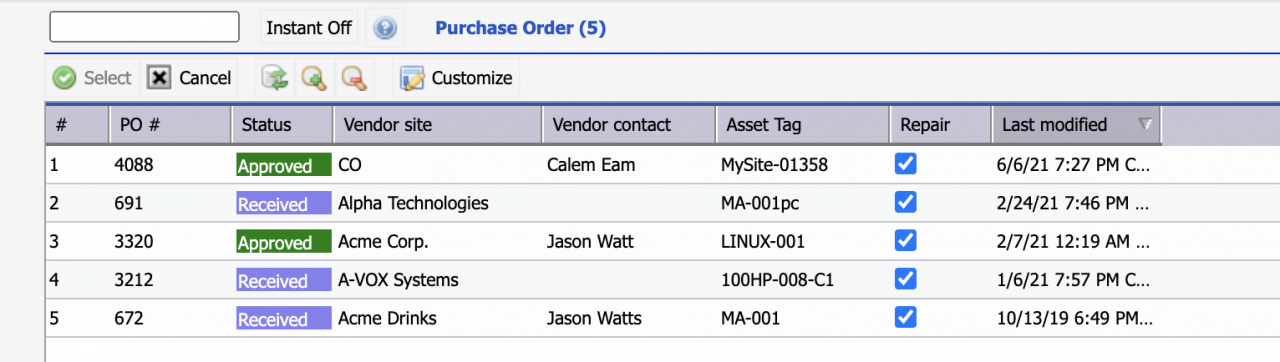

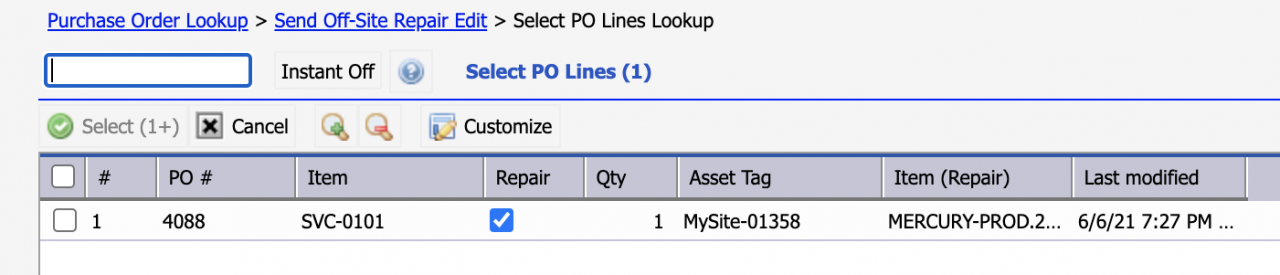

- Menu path: Inventory | Transactions | Send Off-Site Repair

- Select a part to send by its PO

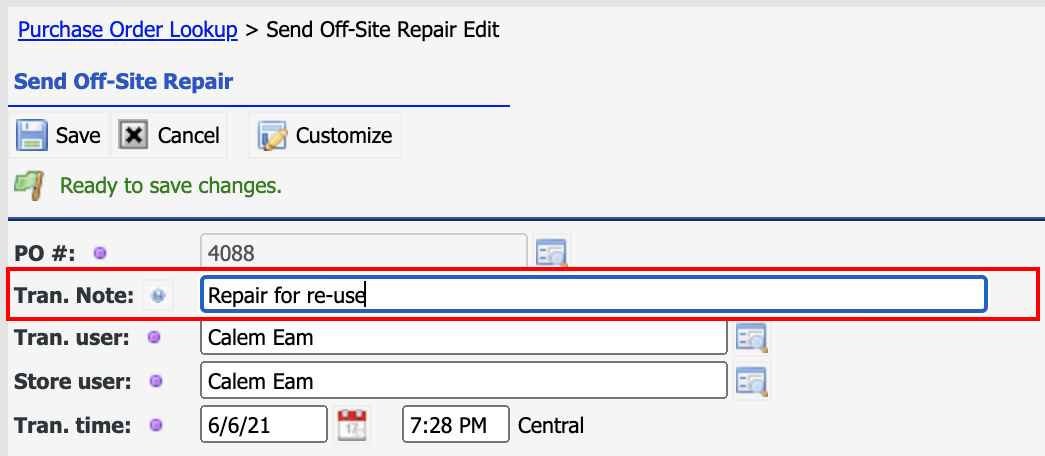

- Optionally add a note for the send transaction.

- Click "Save" to continue

- The PO line is shown to be sent for off-site repair

- Select items to send

- Click "Select (1+)" to send the PO line for off-site repair

2.8 Receive Off-Site Repair

Items from off-site repair are received to stock after they are sent back from vendor.

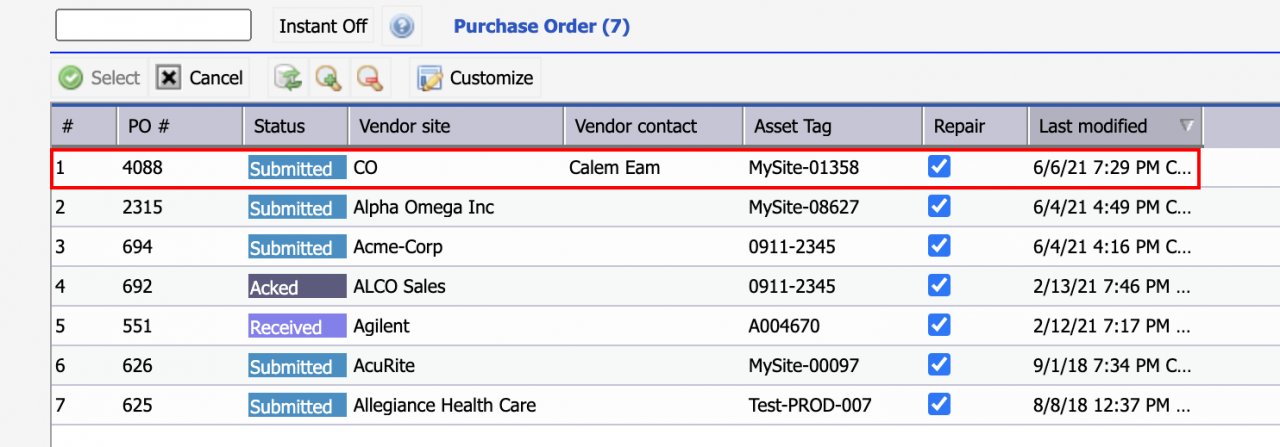

- Menu path: Inventory | Transactions | Receive Off-Site Repair

- Select the PO to receive

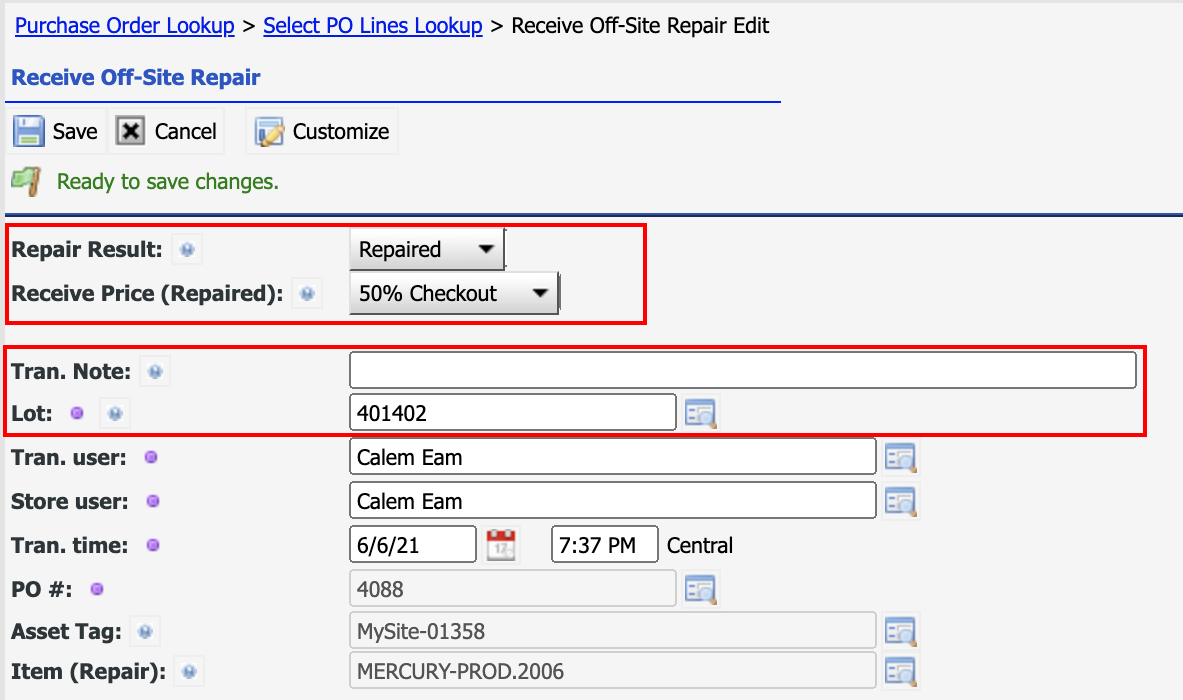

- Select how the item is repaired: repaired, or replaced.

- Select pricing to use to receive the repaired item:

- Checkout price

- 0 (No value)

- 50% Checkout (50% of the checkout value)

- Custom (custom price)

- Set the lot number to receive the item if the item is lot controlled.

- For example, you may create a lot of "Repaired" to track items by its repairing status.

- To track part prices based on repair status, one has to enable "Lot-Priced" at the site inventory.

- See this blog for managing prices by lot

- Click "Save" to pick a stock bin to receive the part.

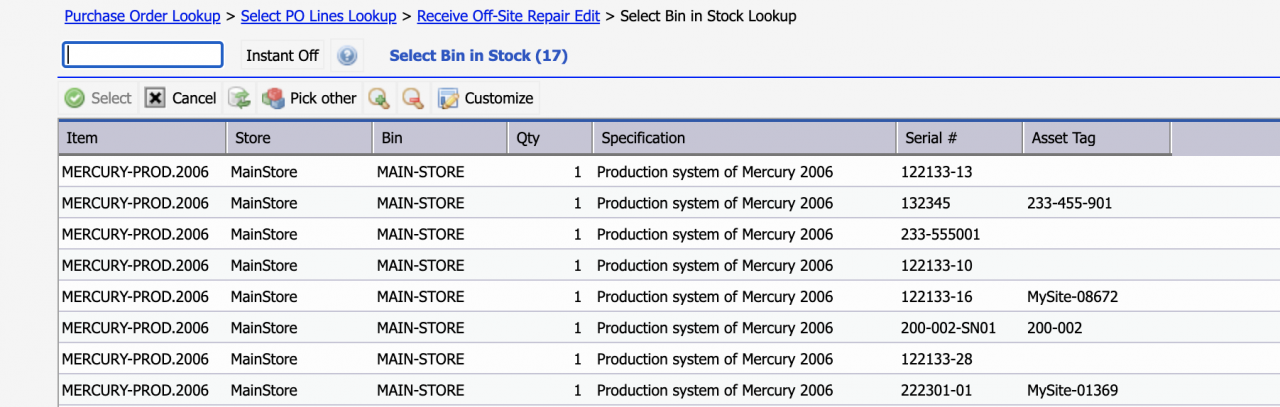

- Select a stock bin (or by its history use of bin) to complete the receive transaction.

- The repaired part is received to stock

- The PO cost (repair cost) is received to the repair work order of the part.

3. Asset Internal and Off-Site Repair

The repair process flows for asset parts are the same as the ones discussed above for non-asset parts. Asset parts are managed with both asset tag and serial numbers. See this blog for asset tracking.

4. Tracking Repaired Parts in Inventory

There are options to track repaired parts in Calem:

- A lot number (New/Used) may be enabled for repaired items.

- A repair storeroom may be created to hold repaired items. The storeroom may be a separate physical storeroom, or an area of a warehouse.

5. Tracking the Cost of Repaired Parts

There are options to track the costs of repaired parts:

- When return a repaired parts to inventory a price may be optionally set. It adjusts the total valuation of your inventory due to the loss of a part value after a repair.

- If you want to track the cost of each repaired part, enable lot-priced for the inventory (see How to Use Price Lot in Calem in the resources below). This option is only applicable to non-asset parts. Each asset part is tracked individually in inventory.

- It is possible to use a repair storeroom to store repaired parts, and set a unit price for each part repaired. The unit price per part at this storeroom will be used for checkout.

6. Part Repair for Parts not in Inventory

Part repair process in Section 2 above streamlines the part checkout from inventory and its work order creation.

- For a part in storeroom a checkout transaction is performed and a repair work order is created.

- Menu: Inventory | Transactions | Create Repair WO (Part in Stock).

- For a part checked out already a repair work order is created based on the checkout transaction.

- Menu: Inventory | Transactions | Create Repair WO (Part Checked Out)

For a part a) not in storeroom, and b) with no record of checkout, the repair processes above do not apply. The first step is to move the part to inventory. There are two options to do it. Option 1 is a good choice. Once the part is in storeroom you may initiate its repair process.

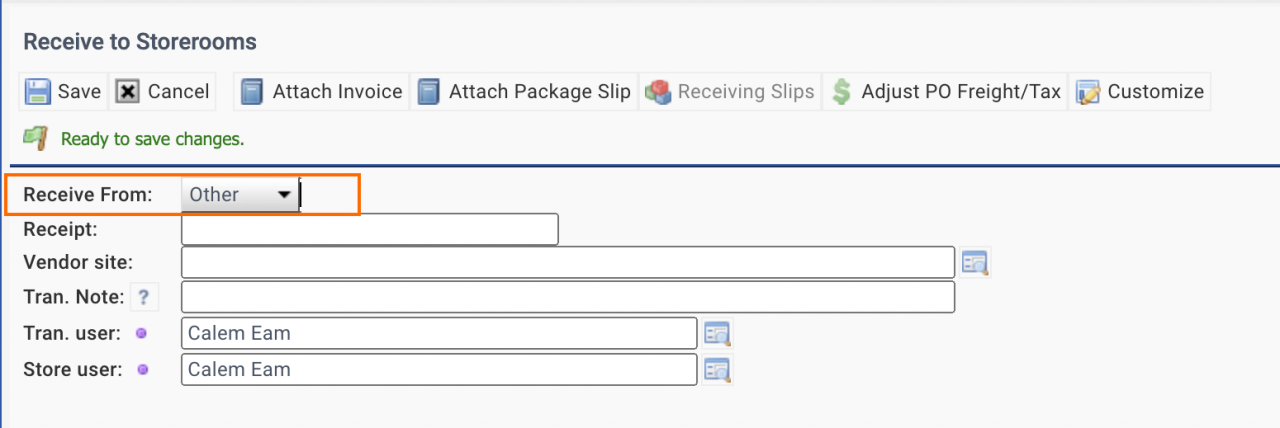

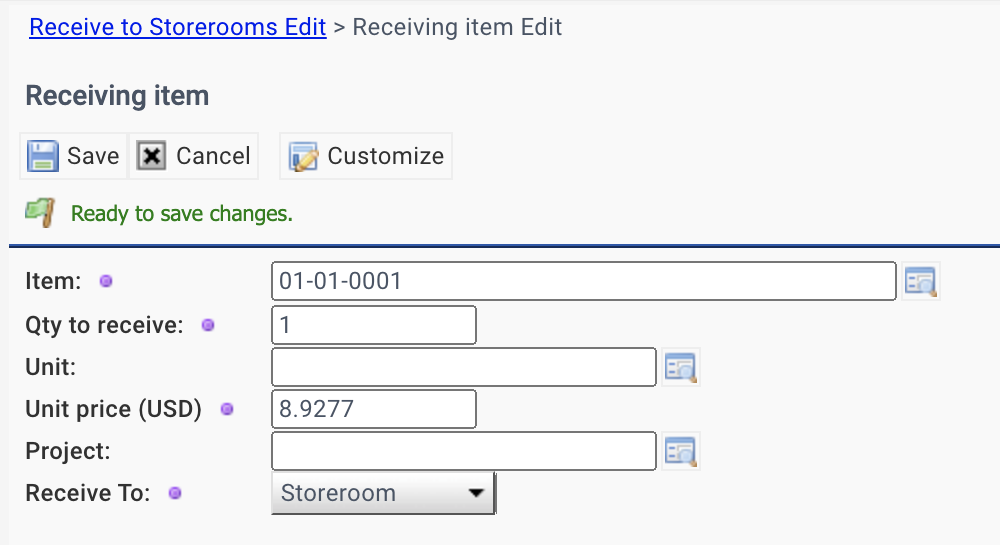

- Option 1: Receive the part to inventory.

- Menu: Inventory | Transactions | Receive to Storerooms

- Select "Other" in the receive-from dropdown

- Enter item number and price to receive it

- Option 2: Take the part to storeroom and perform a physical count to add the part

- Menu: Inventory | Transactions | Physical Count

7. Part Repair for Many Parts

Each repair work order is required to repair a part. To repair many parts create a repair work order for each part. All these work orders can be placed into one requisition. Alternatively, you may spread them into more than one requisition depending on the vendors to repair them. See this blog for more info.

Resources

- Multiple Lines for a Service or Repair Item in a Requisition/PO

- How to Track Asset Off-Site Repairs

- How to Use Price Lot in Calem

- Work Order Life-Cycle Diagrams

- Asset Tracking in Calem

- User Guide and Admin Guide (customer account required)

- Calem Enterprise Training Site

- Calem Enterprise Blogs

- Calem Enterprise demo

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://eam.calemeam.com/